|

•

|

Stress-Life analysis for high-cycle fatigue. The result is a lifetime prediction in terms of the number of cycles to fatigue.

|

|

•

|

Strain-Life analysis for low-cycle fatigue. The result is a lifetime prediction in terms of the number of cycles to fatigue.

|

|

•

|

Stress-Based analysis for high-cycle fatigue. The result is a usage factor, which tells you how close to the fatigue limit the load cycle is.

|

|

•

|

Strain-Based analysis for low-cycle fatigue. The result is a lifetime prediction in terms of the number of cycles to fatigue.

|

|

•

|

Energy-Based analysis when the dissipated energy controls crack formation and growth. The results are a lifetime prediction in terms of the number of cycles to failure and a dissipated fatigue energy density.

|

|

•

|

Cumulative Damage analysis for variable load history. The results are a usage factor, a stress distribution, and a fatigue usage distribution. The last two parameters present an overview of the stress variation in the load history and how damaging different cycles are. The usage factor is a relation between an accumulated damage and a damage that causes fatigue. The distribution variables are visualized with the Matrix Histogram Plot in 2D.

|

|

•

|

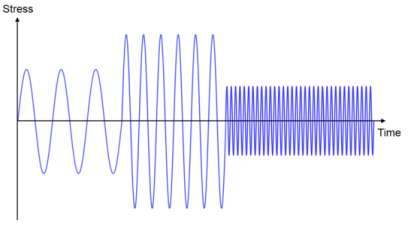

Vibration Fatigue analysis for frequency domain results. Typically, a frequency sweep is made, and it is assumed that the rate of change in frequency is small enough to make the response at any frequency to be considered as steady state. The result is a usage factor, which is a relation between an accumulated damage and a damage that causes fatigue.

|

|

In the Structural Mechanics Module User’s Guide:

In the Multibody Dynamics Module User’s Guide:

|