|

•

|

|

•

|

|

•

|

When the selection entity is set to boundary, select Search annular shape only to detect holes that have surrounding boundaries with annular shapes. The center of the inner and outer circles may differ within a certain tolerance (Annular center offset).

|

|

•

|

Split the selections into several Fasteners nodes.

|

|

•

|

In the Advanced section in the settings for Fasteners, change the Search method to Manual, and set a suitable Search distance.

|

|

•

|

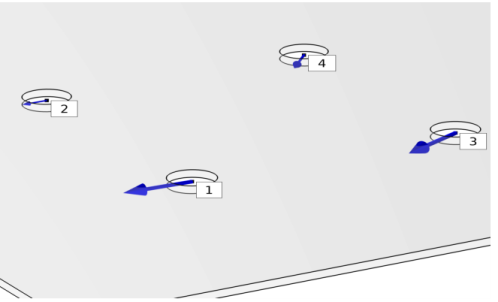

A Fasteners Forces plot group, to visualize the normal and shear forces at each fastener, and a label showing each fastener number. Normal forces are plotted as green arrows, and shear forces as blue arrows. The coloring can be affected by the addition of a Safety subnode. To display the fasteners forces, these have to be evaluated first using the Fasteners Normal Forces and Fasteners Shear Forces evaluation group.

|

|

•

|

A Fasteners Normal Forces evaluation group that contains a table of the location, the normal forces, and the damage index of all fasteners. This table has to be evaluated to display the forces in the Fasteners Forces plot group.

|

|

•

|

A Fasteners Shear Forces evaluation group that contains a table of the location, the shear forces, and the damage index of all fasteners. This table has to be evaluated to display the forces in the Fasteners Forces plot group.

|

|

•

|

A Fasteners Forces Magnitude evaluation group that contains a table of the normal and shear forces magnitude of all fasteners. In the table, click Show Row Numbers to display the number of each fastener.

|