You are viewing the documentation for an older COMSOL version. The latest version is

available here.

The Cam-clay material model was developed in the 1970s at the University of Cambridge, and since then it has experienced many modifications. The Modified Cam-Clay (MCC) model is the most commonly used model due to its smooth yield surface, and it is the one implemented in COMSOL Multiphysics.

The modified Cam-clay model is a so-called critical state model, where the loading and unloading of the material follow different paths in stress space. The model also features hardening and softening of clays. Different formulations can be found in textbooks, see for instance

Ref. 15,

Ref. 16, and

Ref. 17.

This is an ellipse in the pq-plane, with a cross section independent of the Lode angle. Note that

p,

q, and

pc are positive variables.

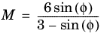

The parameter M > 0 defines the slope of the

critical state line in the

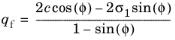

pq-plane. This parameter can be matched to the angle of internal friction

ϕ in the Mohr–Coulomb criterion as

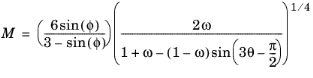

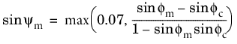

(3-112)

|

|

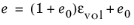

The void ratio e is the ratio between the pore space and solid volume. It can be written in terms of the porosity ε as e = ε/(1 − ε).

|

The compression index λ is the slope of the

virgin isotropic consolidation line, and the swelling index

κ is the slope of the

swelling line (also called unloading-reloading line) in the

e versus

ln(

p) plane. The reference void ratio

eref is measured at the reference pressure

pref and initial void ratio

e0 is measured at the initial mean stress

pi. The starting value of initial mean stress

pi is the reference pressure

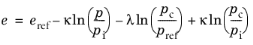

pref. The equation for the virgin isotropic consolidation line is written as

where e0 is the initial void ratio calculated as

|

|

The initial void ratio e0 can be directly entered as user input. In this case, the void ratio at initial consolidation pressure, ec0, is not needed as intermediate variable.

|

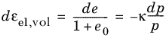

(3-113)

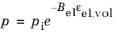

Integrating Equation 3-113, the equation is reformulated as

(3-114)

|

|

The contribution to initial mean stress pi also comes from the first invariant of the initial or external stress tensor of Initial Stress and Strain or External Stress feature. The reference pressure is generally a unit pressure in the used unit system, in the literature the value varies from 1 kPa to 100 kPa. In COMSOL Multiphysics the default value is 100 kPa.

|

At zero volumetric elastic strain and with zero contribution from Initial Stress and Strain or

External Stress features the initial mean stress is nonzero and equal to the reference pressure

pref. The reference pressure acts as an

in situ stress.

(3-115)

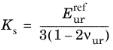

The secant bulk modulus Ks (or bulk modulus

K) is written as

(3-116) or

or

(3-117)

Equation 3-116 is used to compute the void ratio which matches exactly with

Equation 3-117 which may be used for verification purposes.

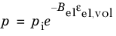

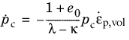

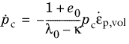

In the modified Cam-clay model, hardening is controlled by the consolidation pressure pc, which depends on the volumetric plastic strain

εp,vol as

(3-118)

The evolution of the consolidation pressure depends on the values for the initial void ratio e0, the

swelling index κ, and the

compression index λ, which are positive parameters that fulfill

and

and

|

|

If an Initial Stress and Strain node is added to the Cam-clay material, the initial consolidation pressure pc0 must be equal or larger than one third of minus the trace of the initial stress tensor, otherwise the initial stress state is outside the Cam-clay ellipse.

|

Here, σ is the stress tensor,

ε is the total strain tensor,

εel is the elastic strain tensor,

σ0 is the initial or external stress tensor, and

G is the shear modulus.

At zero volumetric strain, and with zero contribution from Initial Stress and Strain or

External Stress features, the pressure in the MCC model is equal to the reference pressure (see

Equation 3-114 and

Equation 3-115). This is needed as the MCC model do not have stiffness at zero stress. The reference pressure appears as an additional term in the variational formulation (weak equation).

As opposed to the Linear Elastic Material, the MCC model introduces a nonlinear relation for the hydrostatic pressure as a function of the volumetric elastic strain given by

Equation 3-114.

The plastic strain tensor εp is computed from the flow rule

where λp is the plastic multiplier and the derivatives of the plastic potential

Qp with respect to the stress tensor

σ. An associated flow rule is used such that

Qp =

Fy.

This relation explains why there is isotropic hardening when the pressure is

p > pc/2 and

isotropic softening when

p < pc/2. As opposed to what happens in

J2 plasticity, in the modified Cam-clay soil model the volumetric plastic strain can either increase or decrease as plastic deformation occurs.

When an external pore pressure pf is added to the MCC material, the yield function is shifted along the

p axis, and the yield function reads:

The quantity p − pf is normally regarded as the

effective pressure, or effective stress, which should not be confused with the equivalent von Mises stress. To add the effect of a fluid pressure in the pores

pf to the modified Cam-clay material, add an

External Stress feature.

The Structured Cam-Clay (SCC) model was developed (

Ref. 22,

Ref. 23) to circumvent the limitations of the Cam-clay model when applied to structured soils and clays. The SCC model, however, does not consider the influence of the soil structure neither on strength characteristics (especially cohesion) nor in the softening behavior, and it is also not suitable to model cemented clays.

The Modified Structured Cam-Clay (MSCC) model was further developed to model destructured, naturally structured and artificially structured clays (

Ref. 22), and it is the one implemented in the Geomechanics Module.

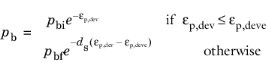

In the MSCC model, the reduction of mean effective stress due to structure degradation, pb, depends on the shear plastic strain

εp,dev. The destructuring mechanism is the process of reducing structure strength due to the degradation and crushing of the structure. The structure degradation is given by

(3-119)

Here, pbi is the initial structural strength,

pbf the failure structural strength,

εp,devc is the equivalent plastic strain at failure, and

ds is the destructuring index due to shear deformation.

where is e void ratio of the structured clay,

Δe is additional void ratio,

e* is void ratio of the destructured clay at the same stress state. The void ratio can be found by using

Equation 3-117. Further,

Δei is the additional void ratio at consolidation pressure, and

dv is the destructuring index due to volumetric deformation.

Here, ς is a parameter to smooth the shape of the plastic potential. The slope of the critical state line,

M can be found by using

Equation 3-112.

Here, λ* is the compression index for destructured clay,

κ is the swelling index, and

η is ratio of shear stress to mean stress.

(3-120) with

with

At zero volumetric strain, and with zero contribution from Initial Stress and Strain or

External Stress features, the pressure in the MSCC model is equal to the reference pressure (see

Equation 3-120 and

Equation 3-115). This is needed as the MSCC model do not have stiffness at zero stress. The reference pressure appears as an additional term in the variational formulation (weak equation).

The Barcelona Basic Model (BBM) was developed to simulate the loading of unsaturated and partially saturated soils, by incorporating an extra state variable for the pore suction. The suction value depends on the amount of water in the soil, and it affects the flow in porous soils as well as the deformation and stress distribution.

The BBM model uses the concepts of plasticity theory, incorporating the critical state model (Ref. 24). This soil model matches the results obtained with the modified Cam-clay model in fully saturated soils.

The so-called Extended Barcelona Basic Model (BBMx) was further developed to overcome numerical limitations of the original BBM model (

Ref. 25). The model implemented in COMSOL Multiphysics follows

Ref. 25 with certain modifications described in this section.

Here, p and

q are stress invariants as defined in

The Modified Cam-Clay Soil Model,

pcs is the consolidation pressure at current suction,

ps is the tensile strength due to current suction,

s is the current suction,

b is a dimensionless smoothing parameter,

sy is the yield value at current suction, and

pref is the reference pressure at which the reference void ratio

eref was measured.

The tensile strength due to current suction, ps, is linearly related to the suction level as

ps =

ks, where

k is the tension to suction ratio.

where λ(s) is the compression index at current suction,

λ0 is the compression index at saturation, and

κ is the swelling index. The compression index at current suction,

λ(s), is given by

where w and

m are weighting and soil stiffness parameters.

The slope of the critical state line M can be computed from the Matsuoka–Nakai criterion, in which case it depends on both the Lode angle

θ and the angle of internal friction

ϕ

(3-121)

At the tensile or compressive meridians, where the Lode angle is θ =

0 or

θ =

π/3, the slope of the critical state line achieves the same expression as when matched to

The Mohr–Coulomb Criterion, see

Equation 3-112

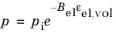

As in The Modified Cam-Clay Soil Model, hardening is controlled by the evolution of the consolidation pressure

pc, which depends on the volumetric plastic strain

εp,vol.

(3-122)

The initial void ratio e0, the swelling index

κ, and the compression index at saturation

λ0, are positive parameters.

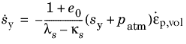

The evolution of the yield value at current suction, sy, is also governed by the volumetric plastic strain

εpl,vol as

(3-123)

Here, λs is the compression index for changes in suction,

κs is the swelling index for changes in suction, and

patm is the atmospheric pressure, all positive parameters. Note that

Equation 3-122 and

Equation 3-123 are normally given with opposite sign. Here, however, the structural mechanics convention is used, so the increments in consolidation pressure and suction are positive in compression.

Here K is the bulk modulus, and

Kcs the stiffness to suction. Note that the pressure

p in compression and suction

s is positive variables, but the elastic volumetric strain

εel,vol is negative in compression. The volumetric elastic response due to suction is given by

Here, s0 is the initial suction. The volumetric elastic response due to suction is accounted in the total strain tensor for BBMx model, so any changes in suction with keeping pressure constant can cause volumetric strains.

(3-124) with

with

At zero volumetric strain, and with zero contribution from Initial Stress and Strain or

External Stress features, the pressure in the BBMx model is equal to the reference pressure (see

Equation 3-124 and

Equation 3-115). This is needed as the BBMx model does not have stiffness at zero stress. The reference pressure appears as an additional term in the variational formulation (weak equation form).

|

|

Note that the material property λ0 is the compression index at saturation, which does not depend on the suction. The variable λ(s), which is a function of the current suction, is the compression index (slope) in the void ratio versus logarithm of the mean stress plot. The material property λs is the compression index (slope) in the void ratio versus logarithm of the matrix suction plot, which does not depend on the mean stress.

|

The Hardening Soil model is an elastoplastic material model with a stress and stress path-dependent stiffness. It is a so-called double stiffness model, meaning that the soil stiffness is different during primary loading and unloading/reloading load paths (

Ref. 26).

In the original hardening soil model, failure in shear occurs according to The Mohr–Coulomb Criterion. In the so-called

Hardening Soil Smooth model (

Ref. 26), failure in shear occurs according to the

The Matsuoka–Nakai Criterion. In

Ref. 28, the so-called Panteghini and Lagioia version of Matsuoka–Nakai criterion is used.

The 50% failure stiffness for primary loading,

E50, and the

stiffness for unloading and reloading,

Eur, are used to define the plastic potential and failure criterion. These are given by

Here  is the reference failure stiffness

is the reference failure stiffness for primary loading at reference pressure,

is the

reference stiffness for unloading and reloading at reference pressure,

c is the cohesion,

ϕ is the angle of internal friction, and

m is the stress exponent.

and

and

where Rf is the failure ratio. Consider the stress invariants

and

, the yield function and plastic potential for the shear hardening are given by

where γp is the accumulated plastic shear strain and

ψm is the

mobilized dilatancy angle.

Here, Rc is the ellipse aspect ratio, and it can directly entered, or given in terms of the

coefficient of earth pressure at rest

The internal variables pc and

γp depend on the volumetric plastic strain

εpl,vol and the plastic strain invariant

J2 (εpl), and their evolution is defined as

where H is the hardening modulus which depends on the bulk modulus in compression

Kc and the bulk modulus in swelling

Ks

where

where

where C is a function of the stiffness modulus

Eur and Poisson’s ratio

ν.

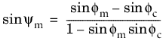

The mobilized dilatancy angle ψm is explicitly used in the definition for the plastic potential

Qp. Different authors define this variable using different expressions. The original expression for the mobilized dilatancy derived by Rowe (

Ref. 26) is

(3-125)

here, ϕc is the

critical friction angle and

ϕm is the

mobilized friction angle, and these are derived from

where ψ is the dilatancy angle,

σi are the principal stresses,

c is the cohesion, and

ϕ is the angle of internal friction.

(3-126)

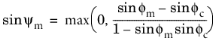

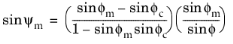

Other expressions (Ref. 26) for the mobilized dilatancy angle include the Wehnert correction

(3-127)

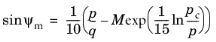

(3-128)

(3-129)

The Rowe–Li–Dafalias model uses Equation 3-126 to define the mobilized dilatancy angle when

, and

Equation 3-129 otherwise.

The Hardening Soil Small Strain model is a combination of

Small Strain Overlay model and

The Hardening Soil Model.

Here  is the reference initial shear modulus for primary loading at reference pressure, c

is the reference initial shear modulus for primary loading at reference pressure, c is the cohesion,

ϕ is the angle of internal friction, and

m is the stress exponent.

The critical shear strain, defined as

here, Gur is the shear modulus for unloading/reloading, as defined in the

The Hardening Soil Model.