|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file pemfc_serpentine_flow_field_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Parameters section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file pemfc_serpentine_flow_field_physics_parameters.txt.

|

|

1

|

|

2

|

|

3

|

In the tree, select Fuel Cell and Electrolyzer>Polymer Electrolytes>Nafion, EW 1100, Vapor Equilibrated, Protonated.

|

|

4

|

|

5

|

|

1

|

|

2

|

Find the Transport mechanisms subsection. Select the Use Darcy’s Law for momentum transport check box.

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Geometry 1 node, then click Component 1 (comp1)>Hydrogen Fuel Cell (fc)>Membrane 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc)>Membrane 1 click Initial Values 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Water Absorption-Desorption, H2 Side, locate the Absorption-Desorption Condition section.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Water Absorption-Desorption, O2 Side, locate the Absorption-Desorption Condition section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Thin H2 Gas Diffusion Electrode Reaction, locate the Electrode Kinetics section.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Thin O2 Gas Diffusion Electrode Reaction, locate the Electrode Kinetics section.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc)>H2 Gas Phase 1 click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc)>O2 Gas Phase 1 click Initial Values 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Chemical potential (comp1.fc.mu0).

|

|

6

|

|

7

|

|

8

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Electrolyte potential (comp1.fc.phil).

|

|

9

|

|

10

|

|

11

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Electric potential (comp1.fc.phis).

|

|

12

|

|

13

|

|

14

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Mass fraction (comp1.fc.wH2O_H2).

|

|

15

|

|

16

|

|

17

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Mass fraction (comp1.fc.wH2O_O2).

|

|

18

|

|

19

|

|

20

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Mass fraction (comp1.fc.wN2_O2).

|

|

21

|

|

22

|

|

23

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Electric potential on boundary (comp1.fc.ecph1.ec1.phis0).

|

|

24

|

|

25

|

|

26

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Boundary mass fraction (comp1.fc.h2gasph1.h2in1.wbndH2O).

|

|

27

|

|

28

|

|

29

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Boundary mass fraction (comp1.fc.o2gasph1.o2in1.wbndH2O).

|

|

30

|

|

31

|

|

32

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 click Boundary mass fraction (comp1.fc.o2gasph1.o2in1.wbndN2).

|

|

33

|

|

34

|

|

35

|

|

36

|

|

1

|

|

2

|

|

3

|

|

1

|

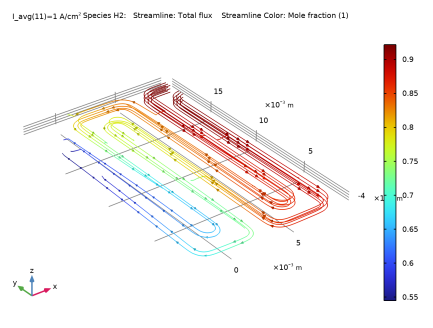

In the Model Builder window, expand the Mole Fraction, H2, Streamline (fc) node, then click Streamline 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Arrow distribution list, choose Equal time.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Mole Fraction, O2, Streamline (fc) node, then click Streamline 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Arrow distribution list, choose Equal time.

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

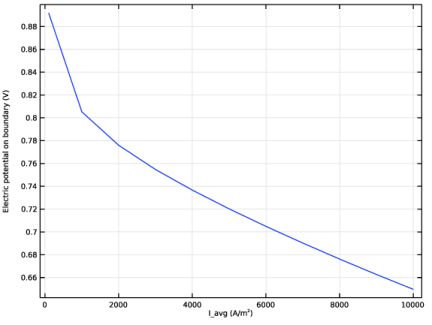

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.phis0_ec1 - Electric potential on boundary - V.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

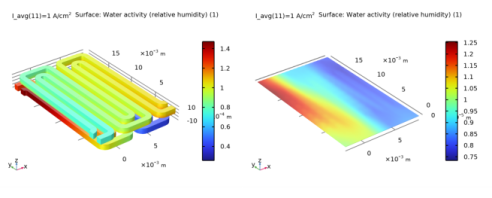

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.aw - Water activity (relative humidity).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Membrane Water Activity>Surface 1 node, then click Selection 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>Membrane transport>fc.aw_mem - Water activity (relative humidity).

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

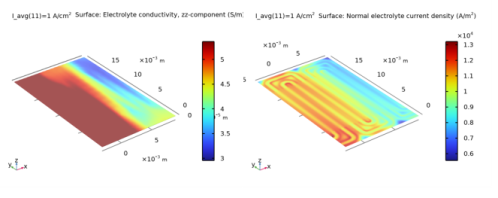

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>Electrolyte conductivity - S/m>fc.sigmalzz - Electrolyte conductivity, zz-component.

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Cross-Membrane Current Density in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>fc.nIl - Normal electrolyte current density - A/m².

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Study 1>Solver Configurations right-click Solution 1 (sol1) and choose Solution>Copy.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Chemical potential (comp1.fc.mu0).

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

19

|

|

20

|

|

21

|

|

22

|

|

23

|

|

24

|

|

25

|

|

26

|

|

27

|

|

28

|

|

29

|

|

30

|

|

31

|

|

32

|

|

33

|

|

34

|

|

35

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|