|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file soec_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file soec_physics_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

5

|

Locate the H2 Gas Mixture section. Find the Transport mechanisms subsection. Clear the Include gas phase diffusion check box.

|

|

1

|

|

1

|

|

2

|

|

3

|

In the tree, select Fuel Cell and Electrolyzer>Solid Oxides>Yttria-Stabilized Zirconia, 8YSZ, (ZrO2)0.92-(Y2O3)0.08.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for H2 Gas Diffusion Electrode Reaction, locate the Electrode Kinetics section.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for O2 Gas Diffusion Electrode Reaction, locate the Electrode Kinetics section.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Water Electrolyzer (we) click Electronic Conducting Phase 1.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Paste Selection dialog box, type 21-23, 25, 28-30, 32, 35-37, 39 in the Selection text field.

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1 right-click Boundary Layers 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Boundary Layers 2 node, then click Boundary Layer Properties.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Paste Selection dialog box, type 14-18, 24, 31, 38, 41, 43-45, 47, 49, 51, 52 in the Selection text field.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Mesh 1>Swept 2 right-click Distribution 1 and choose Duplicate.

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the H2 Gas Mixture section. Find the Transport mechanisms subsection. Select the Include gas phase diffusion check box.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 3 node.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

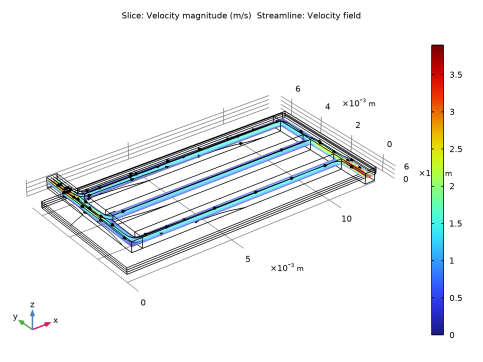

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Free and Porous Media Flow>Velocity and pressure>u,v,w - Velocity field.

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

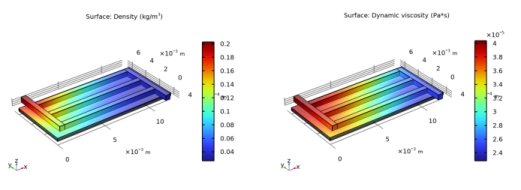

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Free and Porous Media Flow>Material properties>fp.rho - Density - kg/m³.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Free and Porous Media Flow>Material properties>fp.mu - Dynamic viscosity - Pa·s.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

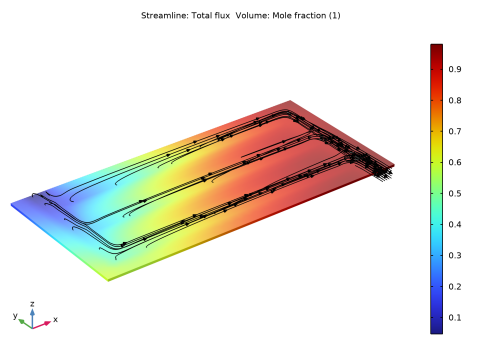

In the Settings window for Streamline, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Water Electrolyzer>Species H2>we.tfluxH2x,...,we.tfluxH2z - Total flux.

|

|

3

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Water Electrolyzer>Species H2>we.xH2 - Mole fraction.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Cross-Sectional Electrolyte Current Density in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Water Electrolyzer>Electrolyte current density vector - A/m²>we.Ilz - Electrolyte current density vector, z-component.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file soec_geom_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

Right-click Component 1 (comp1)>Geometry 1>Work Plane 1 (wp1)>Plane Geometry>Rectangle 1 (r1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Select the object r3 only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Distances section. In the table, enter the following settings:

|

|

4

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 19 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object fin, select Boundary 42 only.

|

|

1

|

|

2

|

In the Settings window for Explicit Selection, type Cathode Current Collector in the Label text field.

|

|

3

|

|

4

|

On the object fin, select Boundaries 10, 26, 33, and 40 only.

|

|

1

|

|

2

|

In the Settings window for Explicit Selection, type Anode Current Collector in the Label text field.

|

|

3

|

|

4

|

On the object fin, select Boundary 3 only.

|