|

|

•

|

unventilated cavities, completely closed or connected either to the exterior or to the interior by a slit with a width not exceeding 2 mm;

|

|

•

|

slightly ventilated cavities, connected either to the exterior or to the interior by a slit greater than 2 mm but not exceeding 10 mm;

|

|

•

|

well-ventilated cavities, corresponding to a configuration not covered by one of the two preceding types, it is assumed that the whole surface is exposed to the environment so that boundary conditions are applied to (see the Boundary conditions section below for more information).

|

|

•

|

|

•

|

|

•

|

ΔT is the maximum surface temperature difference in the cavity

|

|

•

|

|

•

|

Tm is the average temperature on the boundaries of the cavity

|

|

•

|

E is the intersurface emittance, defined by:

|

|

•

|

|

•

|

F is the view factor of the rectangular section, defined by:

|

|

•

|

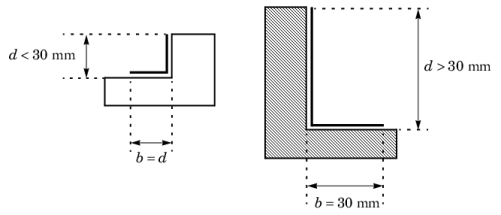

d is the cavity dimension in the heat flow rate direction

|

|

•

|

b is the cavity dimension perpendicular to the heat flow rate direction

|

|

•

|

|

•

|

|

•

|

The linear thermal transmittance of the frame Ψ defined by:

|

|

L2D (W/(m·K))

|

|||

|

L2D (W/(m·K))

|

|||

|

Ψ (W/(m2·K))

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file window_and_glazing_thermal_performances_preset.mph.

|

|

1

|

In the Model Builder window, expand the Window with Insulation Panel (comp1)>Definitions node, then click Variables 1.

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, expand the Heat Transfer in Solids and Fluids (ht) node, then click Fluid 1.

|

|

3

|

|

4

|

In the Settings window for Heat Transfer in Solids and Fluids, click to expand the Discretization section.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

In the Settings window for Global Evaluation, type Thermal Properties, Window with Insulation Panel in the Label text field.

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Window with Glazing (comp2)>Definitions node, then click Variables 2.

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, expand the Heat Transfer in Solids and Fluids 2 (ht2) node, then click Fluid 1.

|

|

3

|

|

4

|

In the Settings window for Heat Transfer in Solids and Fluids, click to expand the Discretization section.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, type Thermal Properties, Window with Glazing in the Label text field.

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|