|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file valve_geom_sequence.mph.

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

•

|

Size — a global attribute node that controls the size of the elements in the entire sequence. A good practice is to use this node to define the coarsest mesh element size you plan to have in the geometry. You can then add downstream Size attribute nodes as needed to apply finer mesh element size settings on selected entities.

|

|

•

|

Size 1 — attribute node to control the element size on specified boundaries. Here, it prescribes a finer mesh element size on the wall boundaries.

|

|

•

|

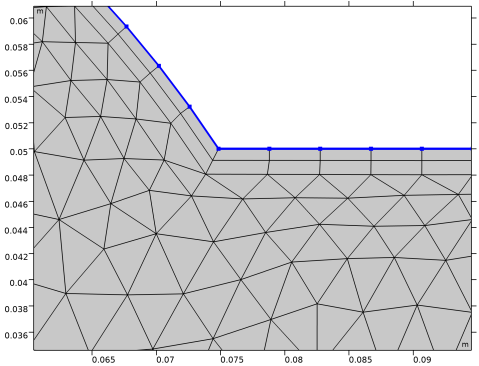

Corner Refinement 1 — attribute node that prescribes a mesh refinement at corners where the adjacent edges form an angle greater than a specified value. It is usually applied to increase the number of elements around corners where the boundary layer mesh is trimmed.

|

|

•

|

Free Triangular 1 — mesh operation to generate an unstructured triangular mesh in the simulation domain.

|

|

•

|

Boundary Layers 1 — mesh operation to insert a boundary layer mesh for selected domains. Contains settings for boundary layer generation in sharp corners.

|

|

•

|

Boundary Layer Properties 1 — local attribute node that contains the selection of boundaries where the boundary layer mesh should be inserted. It also includes settings for layer height and number of layers. Several nodes can be added to specify different boundary layer characteristics on different boundaries.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) > Mesh 1 > Boundary Layers 1 click Boundary Layer Properties 1.

|

|

2

|

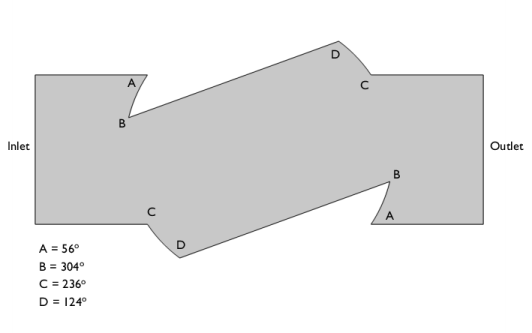

Zoom in around corner C, see Figure 1, in the top right region of the valve to see the inserted boundary layers mesh more clearly.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) > Mesh 1 > Boundary Layers 1 click Boundary Layer Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) > Mesh 1 > Boundary Layers 1 click Boundary Layer Properties 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Zoom in around corner C, see Figure 1, in the top right region of the valve.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

In the Total thickness text field, type 2[mm] to specify the total thickness of layers in the boundary layer.

|

|

11

|

|

12

|

|

13

|

Click

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

3

|

|

4

|

Find the Trimming in narrow corners subsection. In the Trim for angles less than text field, type 65.

|

|

5

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

Select the Filter corners checkbox.

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click to select the

|

|

5

|

Click

|