You are viewing the documentation for an older COMSOL version. The latest version is

available here.

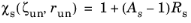

The general constitutive equations for the coupled damage–plasticity model uses the concept of the damaged stress tensor

σd and the

undamaged stress tensor

σun. The former is used in the weak formulation while the latter describe the behavior of the intact material.

where σun is split into a positive and negative part by a spectral decomposition in order to account for the anisotropic behavior of concrete in tension and compression. For the same reason, two damage variables introduced: the tensile damage variable

dt and the compressive damage variable

dc. These variables introduce a weakening of the material’s stiffness, and varies from 0 for an undamaged state to 1 for a fully damaged state. Their definitions are described in

Damage Model.

where, C is the fourth order

elasticity tensor, “:” stands for the double-dot tensor product (or double contraction). The elastic strain

εel is the difference between the total strain

ε and inelastic strains

εinel. The coupled damage–plasticity model always adds a plastic strain tensor

εpl to

εinel, but other contributions such as thermal strains can also be considered. There may also be an external stress contribution

σex, with contributions from initial, viscoelastic, or other inelastic stresses.

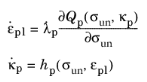

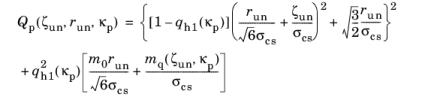

The evolution of the plastic strains are based on the undamaged stress and thus independent of damage. A flow plasticity model with isotropic hardening is used that introduces a yield function Fp,

a plastic potential

Qp, a scalar hardening variable

κp, and the plastic multiplier

λp. The model can be summarized by the following evolution equations for the plastic strain and the hardening variable

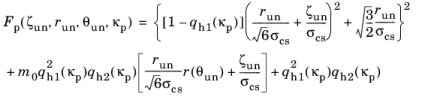

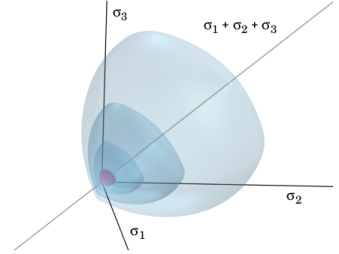

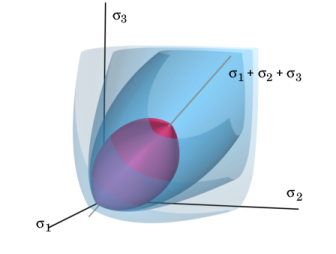

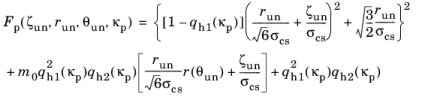

The yield function used is a generalization of The Willam–Warnke Criterion written as a function of the Haigh–Westergaard coordinates in the space of the undamaged stress tensor (

ξun, r

un,

θun), as described in

Invariants of the Stress Tensor, and

κp. It is defined as

(3-104)

where qh1 and

qh2 are dimensionless hardening functions, and

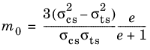

σcs is the uniaxial compressive strength. The friction parameter

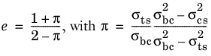

where σts is the uniaxial tensile strength and

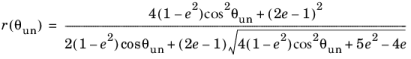

e is the eccentricity parameter. The meridians of the corresponding yield surface

Fp are parabolic, while the deviatoric sections are triangular at low confinement but changes toward a circular shape at high confinement. The shape of the deviatoric section is given by a dimensionless function of the Lode angle

θun

As suggested in Ref. 29 and

Ref. 30, the eccentricity is in COMSOL Multiphysics computed as

where σbc is the biaxial compressive strength.

A graphical representation of yield surface Fp = 0 in the undamaged principal stress space and how evolves during hardening is shown in

Figure 3-23 and

Figure 3-24.

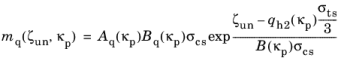

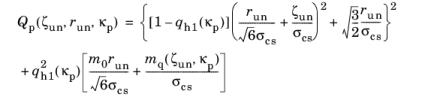

(3-105)

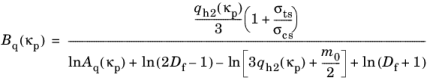

where Aq(

κp) and

Bq(

κp) are auxiliary functions derived from assumptions on the plastic flow in the post-peak regime in uniaxial loading, see

Ref. 30. They are defined as

where Df is a model parameter that controls the dilatancy of the plastic flow. COMSOL Multiphysics by default uses

Df = 0.85.

From this equation it can be seen that the rate of κp depends on the direction of loading such that it grows faster in uniaxial compression while it is constant in uniaxial tension. The rate of

κp is, furthermore, scaled by a ductility measure

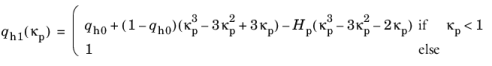

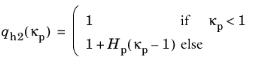

The hardening variable κp enters the two dimensionless hardening functions

qh1 and

qh2 that appear in

Equation 3-104 and

Equation 3-105. These functions control the evolution of the size and shape of the yield function and the plastic potential. They are defined as

where qh0 defines the initial yield limit, and

Hp is a dimensionless hardening modulus that controls the hardening in the post-peak regime. For the functions to be well-defined it is required that 0 <

Hp < (1 -

qh0).

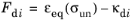

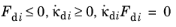

The definition of the two damage variables, dt and

dc, are defined in the framework of isotropic damage mechanics, It can described by a damage loading function

Fdi and Kuhn-Tucker loading-unloading conditions

(3-106)

(3-107)

where i = [

t,

c] for tension and compression, respectively. In the above

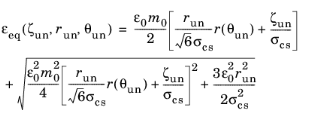

εeq is the equivalent strain and

κdi is a history variable. The damage variables are then defined on the form

where κdi1 and

κdi2 are additional history variables.

where ε0 =

σts /

E. Noteworthy is that this definition of

εeq reduces to

or directly as εeqt =

εeq. The definition of

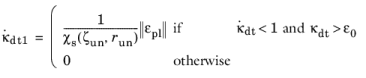

κdt then follows from

Equation 3-106 and

Equation 3-107. The two additional history variables

κdt1 and

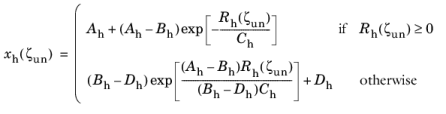

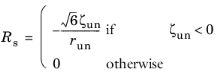

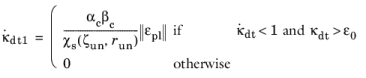

κdt2 are introduced to account for how damage evolves during different stress states. The first variable is a function of the rate of the plastic strain tensor and is given by the evolution equation

(3-108)

In uniaxial compression we get Rs = 1 and

χs =

As, which can be useful for calibrating the model parameter

As. COMSOL Multiphysics by default uses

As = 10.

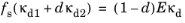

The definition of κdc then follows from

Equation 3-106 and

Equation 3-107. The two additional history variables

κdc1 and

κdc2 are introduced to account for how damage evolves during different stress states. The first variable is a function of the rate of the plastic strain tensor and is given by the evolution equation

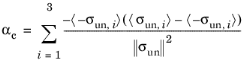

The factor αc is introduced to distinguish between tensile and compressive stress, and follows from the spectral decomposition of

σun as

where σun,i is th

ith principal value of

σun, and “<·>” denote the positive parts operator. Note that

αc varies from 0 in pure tension to 1 in pure compression.

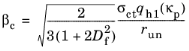

The factor βc is introduced to accomplish a smooth transition between the case of pure damage to damage–plasticity softening, which may occur during cyclic loading. It is defined as

where Df is the same model parameter used for the plasticity flow. The ductility measure

χs is defined in

Equation 3-108.

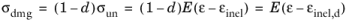

Given the damage history variables, the definition of both damage variables dt and

dc follows the same format and the subscript is dropped for simplicity. Assuming monotonic and uniaxial loading, the damaged stress in the softening regime can be described by an enhanced inelastic strain,

εinel,d, such that

(3-109)

(3-110)

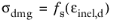

where fs(·) is the softening law; often referred to as a traction-separation law, although here given in a terms of strain since we are working with a continuum.

Now since damage is an irreversible process, it is postulated that εinel,d can be described by the damage history variables. We can call this strain measure the inelastic damage strain (or crack-opening strain) and define it as

Finally, replacing ε -

εinel in

Equation 3-109 with

κd such that

and using it together with Equation 3-110 results in an equation for the damage variable in terms of the known history variables on the form

(3-111)

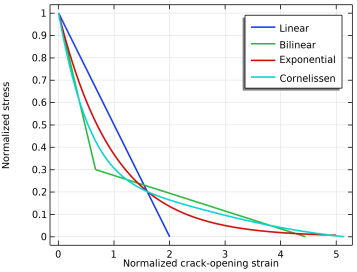

This equation is typically nonlinear and we need to solve it for d using Newton’s method at each material point. COMSOL Multiphysics here provides a number of built-in definitions of

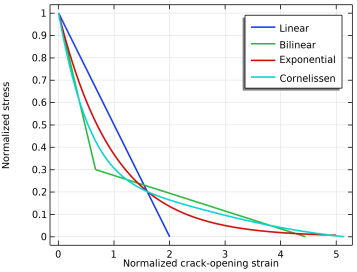

fs(·) for both tension and compression:

These are depicted in a Figure 3-25. The linear and bilinear definitions have closed-form solutions to

Equation 3-111, which makes them computationally attractive since it negates solving a nonlinear equation to find

d.

When combined with the crack-band method, the stress versus strain curves in Figure 3-25 are defined in terms of stress versus displacement. The stress versus displacement curves are then converted to unique stress versus strains curves at each material point using the crack-band width

hcb, see

The Crack Band Method.

In addition to the built-in softening laws, COMSOL Multiphysics allows user-defined definitions of fs(·) and for this purpose provides the variables

<phys>.<feat>.<feat>.edmgt and

<phys>.<feat>.<feat>.edmgc for the damaged strain in tension and compression, respectively. Alternatively, the user-defined softening behavior can be specified in terms of a stress versus displacement curve

fw(·).

Equation 3-111 is then replaced by

assuming that the crack-band method is used. If chosen, COMSOL Multiphysics provides the variables <phys>.<feat>.<feat>.wdmgt and

<phys>.<feat>.<feat>.wdmgc for the damaged displacement in tension and compression, respectively. For both these options, the a nonlinear equation needs to be solved to find

d.