You are viewing the documentation for an older COMSOL version. The latest version is

available here.

For a matrix material described by a Linear Elastic or Nonlinear Elastic materials, a Fiber described by a

Linear Elastic material adds a contribution to the stress tensor of the type

Here, Efib − E is the difference between the stiffness of the isotropic matrix

E and the fibers’ stiffness

Efib,

vfib is the fiber volume fraction,

a is the direction vector for the fiber orientation in the undeformed geometry, and

εa = a ·

εel ·

a is the elastic strain in the fiber direction

a.

For Nonlinear Elastic Materials, the same contribution to the stress tensor is added, although the stress-strain relation in the isotropic matrix could be nonlinear.

When the fiber stiffness is described by a Uniaxial stress function, the added stiffness reads

where σa(εa) is a function of the elastic strain in the fiber direction,

εa = a ·

εel ·

a. A linear elastic fiber can be described by

but in general, σa(εa) could be a nonlinear expression of the fiber strain

εa.

For Hyperelastic Materials, the

Holzapfel–Gasser–Ogden model is available beside the

Linear elastic and

Uniaxial data models for fibers. In this case, the fibers are represented by additional contributions to the strain energy density (

Ref. 29 and

Ref. 30).

Here, Wiso is the strain energy density of the isotropic hyperelastic material. In

Ref. 29 Wiso is represented by a nearly incompressible

Neo-Hookean material; in COMSOL Multiphysics it is possible to select any of the built-in hyperelastic material models.

The second and third terms, Wfib,1 and

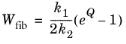

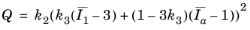

Wfib,2 are anisotropic additions that describe the mechanical contribution of collagen fiber networks. These terms contribute with a strain energy density of the type

where

where

where the parameter k1 represents the fiber stiffness (SI unit: Pa),

k2 is a dimensionless tuning parameter, and

k3 is the fiber dispersion (dimensionless). A value of

k3 = 0 recovers the formulation in

Ref. 29, where all the fibers are perfectly oriented in the

a direction. Setting

k3 = 1/3 means that the fibers are completely dispersed, thus recovering a similar formulation as given in the

Delfino material model.

The invariant  represents the squared value of the isochoric elastic stretch in the fiber direction a

represents the squared value of the isochoric elastic stretch in the fiber direction a. A common modeling assumption for biological tissues is that fibers cannot sustain compression, so the fiber stiffness is added only for tensile stretches such as

.

The hyperelastic formulation in the Holzapfel–Gasser–Ogden constitutive model (Ref. 29 and

Ref. 30) based on the isochoric elastic Cauchy–Green tensor can be problematic when the matrix material is made of a compressible or nearly incompressible material (

Ref. 31 and

Ref. 32).

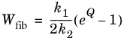

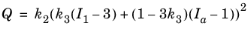

The solution to this problem (Ref. 32) is to relax the isochoric restriction for the fiber deformation, and use the total strain invariant in the fiber direction instead. The contribution to the strain energy density then reads

where

where

The anisotropic strain energy density for the fiber family Wfib can also be specified as a user-defined expression of the strain invariants

Ia,

Ib,

Ic,

Iab,

Iac, and

Ibc, where

here, b and

c are orthogonal directions to the main fiber direction

a.

|

|

The internal variables Ia, Ib, Ic, Iab, Iac, Ibc,  ,  ,  ,  ,  , and  are named item.IaCe, item.IbCe, item.IcCe, item.IabCe, item.IacCe, item.IbcCe, item.IaCIe, item.IbCIe, item.IcCIe, item.IabCIe, item.IacCIe, and item.IbcCIe, respectively. Here, item is the name of the Fiber node (for instance, solid.hmm1.fib1).

|

where Efib − E is the difference between the stiffness of the isotropic matrix

E and the fibers’ stiffness

Efib,

vfib is the fiber volume fraction,

a is the direction vector for the fiber orientation in the undeformed geometry, and

εa = a ⋅ εel ⋅ a is the elastic strain in the fiber direction

a.

where εth,fib is the thermal strain in the fibers. When the fiber stiffness is described by a

Uniaxial stress function, the added stiffness reads

where σa(εa) is a function of the elastic strain in the fiber direction, where

For Nonlinear Elastic Materials, the same contribution to the stress tensor is added, although the stress-strain relation in the isotropic matrix could be nonlinear.

For Hyperelastic Materials containing one fiber family, the anisotropic strain energy density reads:

When Thermal Expansion is added to fibers described by the

Holzapfel–Gasser–Ogden material model, the fiber contribution

Wfib to the strain energy density is computed from the invariants of the elastic Cauchy-Green tensor:

The thermal strain in the fibers, εth,fib, can be specified by different means. When the secant coefficient of thermal expansion is used, it reads

Here, the secant coefficient of thermal expansion αs can be temperature-dependent. The reference temperature

Tref is the temperature at which there are no thermal strains in the fibers, and

Tfib is the current fiber temperature.