|

|

•

|

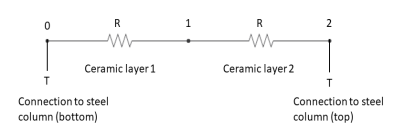

Lumped System Connector, Interface feature in the Heat Transfer in Shells interface, applied on the bottom interface of the top shell, and on the top interface of the bottom shell. This feature uses the heat rate defined by each External Terminal feature to set a heat flux on the corresponding boundary in the distributed finite element model.

|

|

•

|

External Terminal feature in the Lumped Thermal System interface, applied at each extremity of the thermal circuit. This feature prescribes the temperature Text provided by the Lumped System Connector, Interface feature of the Heat Transfer in Shells interface.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Material Link.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Material Link.

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Heat Transfer in Solids (ht) and choose Temperature.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 2 (comp2) right-click Materials and choose Layers>Layered Material Link.

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Materials click Layered Material Link 1 (llmat1).

|

|

2

|

In the Settings window for Layered Material Link, click Section_bar in the upper-right corner of the Layered Material Settings section. From the menu, choose Layer Cross-Section Preview.

|

|

3

|

Locate the Orientation and Position section. From the Position list, choose Bottom side on boundary.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Component Parameters section. From the Specify list, choose Thermal and geometric properties.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Component Parameters section. From the Specify list, choose Thermal and geometric properties.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Heat Transfer in Shells (htlsh) click Solid 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

In the Settings window for Lumped System Connector, Interface, locate the Interface Selection section.

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

In the Settings window for Lumped System Connector, Interface, locate the Interface Selection section.

|

|

4

|

|

5

|

Locate the Terminal Inputs section. From the Pext list, choose External Terminal 2 (term2) (lts/term2).

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Heat Transfer in Shells (htlsh) and Lumped Thermal System (lts).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Temperature, Shell (htlsh) node, then click Volume 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Select the Enable check box.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

|

10

|

Click to expand the Title section. Locate the y-Axis Data section. From the Parameter list, choose Expression.

|

|

11

|

|

12

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

|

20

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|