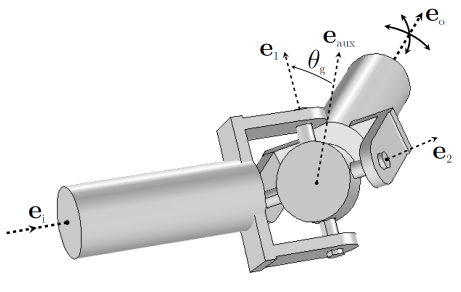

An Universal Joint, also known as Hooke’s joint or Cardan joint, is commonly used to transmit rotational motion between shafts that have different orientations. Physically this joint is made up of a pair of hinge joints, oriented perpendicular to each other, connected by a cross shaft or gimbal. This joint is a kind of abstract joint where the gimbal is not modeled and both the shafts are directly connected to each other. In general, this joint is used to transfer mechanical power from one shaft to another shaft. The added degrees of freedom in this joint are the relative rotations about the two legs of the gimbal that form the joint axis and second axis.