|

|

1

|

|

2

|

In the Application Libraries window, select Corrosion Module>Atmospheric Corrosion>atmospheric_corrosion_busbar_geom in the tree.

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

In the tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

4

|

|

5

|

In the tree, select Electrochemistry>Primary and Secondary Current Distribution>Current Distribution, Shell (cdsh).

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file atmospheric_corrosion_busbar_parameters.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Secondary Current Distribution (cd) and choose Electrode.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the tree, select Built-in>Copper.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Current Distribution, Shell (cdsh) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Anodic Tafel equation.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Kinetics section. From the Kinetics expression type list, choose Cathodic Tafel equation.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Current Distribution, Shell (cdsh) right-click Electrode Surface 2 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary with Initialization.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

|

4

|

|

1

|

|

2

|

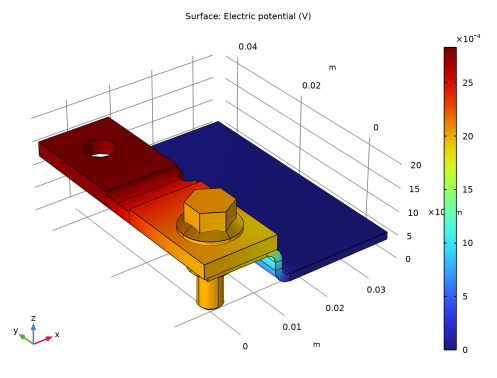

In the Settings window for 3D Plot Group, type Electrode Potential vs. Ground (cd) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.phis - Electric potential - V.

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Electrode Potential vs. Adjacent Reference (cdsh) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Current Distribution, Shell>cdsh.Evsref - Electrode potential vs. adjacent reference - V.

|

|

3

|

|

1

|

|

2

|

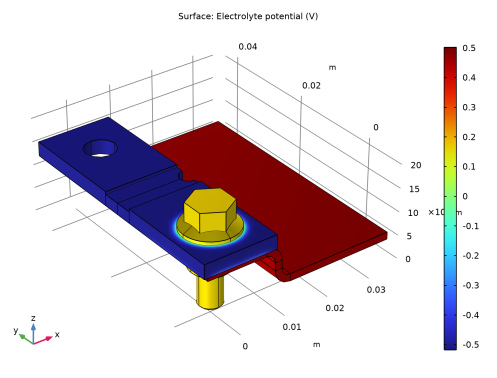

In the Settings window for 3D Plot Group, type Electrolyte Potential in Film (cdsh) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Current Distribution, Shell>phil2 - Electrolyte potential - V.

|

|

3

|

|

1

|

|

2

|

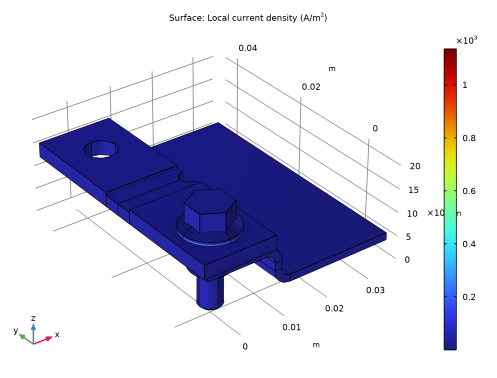

In the Settings window for 3D Plot Group, type Corrosion Current Density (cdsh) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Current Distribution, Shell>Electrode kinetics>cdsh.iloc_er1 - Local current density - A/m².

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Oxygen Reduction Current Density (cdsh) in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Current Distribution, Shell>Electrode kinetics>cdsh.iloc_er2 - Local current density - A/m².

|

|

3

|