|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Current Distribution, Shell (cdsh).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file atmospheric_corrosion_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials>AISI 4340 steel in 0.6M NaCl at pH = 8.3 (mat1)>Local current density (lcd) node, then click Interpolation 1 (iloc_exp).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Materials>AA5083-H131 in 0.6 M NaCl (mat2)>Local current density (lcd) node, then click Interpolation 1 (iloc_exp).

|

|

2

|

|

1

|

|

2

|

In the Settings window for Current Distribution, Shell, click to expand the Physics vs. Materials Reference Electrode Potential section.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Current Distribution, Shell (cdsh) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both boundaries.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click in the Graphics window and then press Ctrl+A to select both boundaries.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

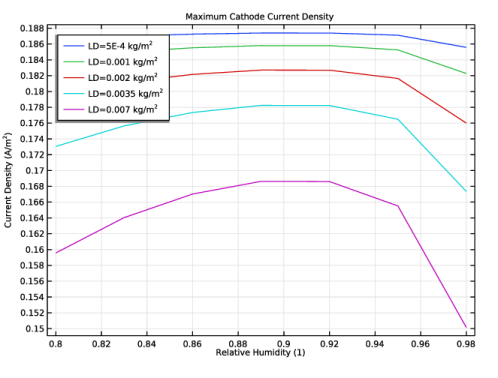

Select the y-axis label check box. In the associated text field, type Current Density (A/m<sup>2</sup>).

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|