|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

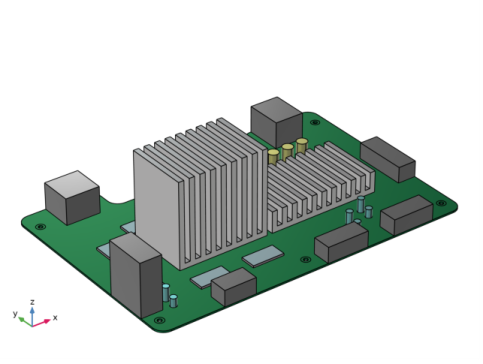

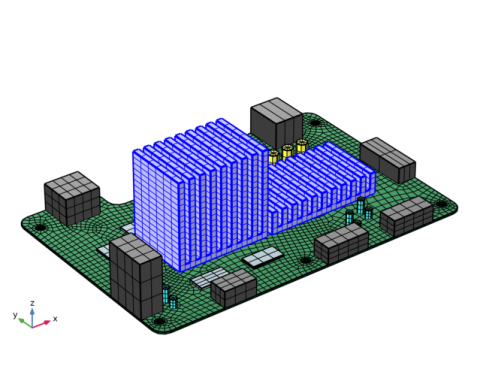

Browse to the model’s Application Libraries folder and double-click the file motherboard_shock_response.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Built-in>Aluminum.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Built-in>Silicon.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the tree, select Built-in>Aluminum.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Material, type Capacitors (larger) composite material in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the tree, select Built-in>Aluminum.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Fixed Constraint.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click the Custom button.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Acceleration (g) vs. Frequency (Hz) in the Label text field.

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file motherboard_shock_response.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Units section. In the table, enter the following settings:

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

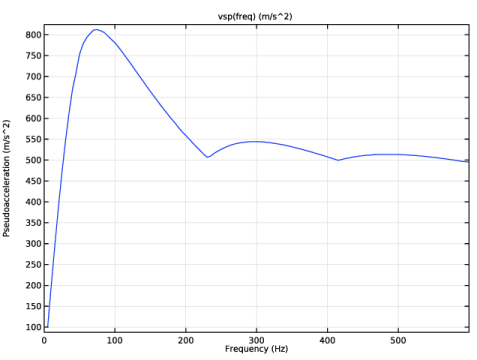

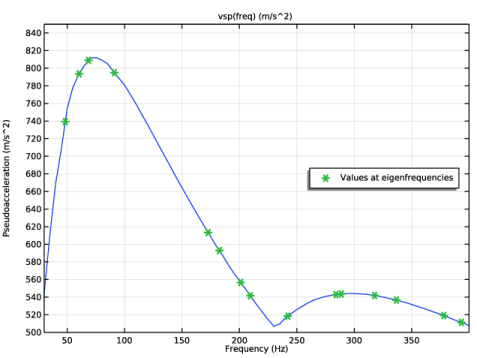

In the associated text field, type Frequency (Hz).

|

|

4

|

|

5

|

In the associated text field, type Pseudoacceleration (m/s^2).

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

8

|

|

1

|

|

1

|

Go to the Table window.

|

|

2

|

|

1

|

|

2

|

|

3

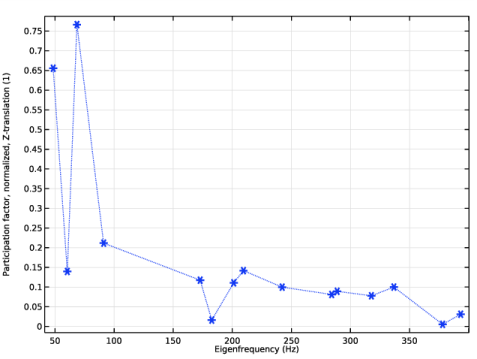

|

|

4

|

|

5

|

Locate the Coloring and Style section. Find the Line markers subsection. From the Marker list, choose Asterisk.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Global definitions>Functions>vsp(freq) - Vertical Spectrum.

|

|

5

|

|

6

|

|

7

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

8

|

|

9

|

|

10

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Response Spectrum 1>Effective modal mass>rsp1.mEffLZ - Effective modal mass, Z-translation - kg.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

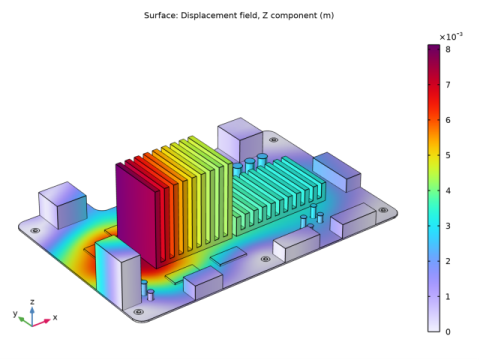

In the Settings window for 3D Plot Group, type Maximum Displacement, Response Spectrum in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Advanced section. In the Load factor text field, type 50*sin(2*pi/22[ms]*t)*(t<11[ms]).

|

|

7

|

Click to expand the Output section. Not storing the time derivative reduces the size of the output data.

|

|

8

|

|

9

|

|

1

|

|

2

|

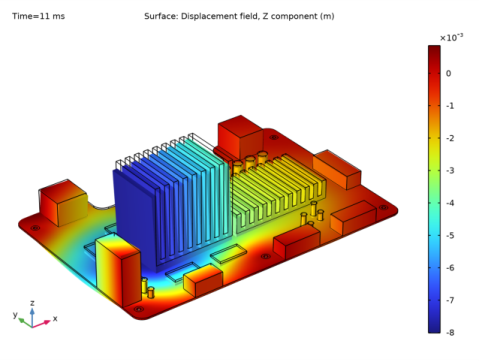

In the Settings window for 3D Plot Group, type Maximum Displacement, Time History in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|