|

|

•

|

A short version, elbow_bracket_brief, treating the three first analysis types in the above list.

|

|

•

|

A complete version, elbow_bracket, treating all nine analysis types.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file elbow_bracket.mphbin.

|

|

6

|

Click

|

|

7

|

|

8

|

Click the

|

|

1

|

|

2

|

On the object fin, select Edges 17, 21, 23, 27, 38, 40, 42, and 44 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

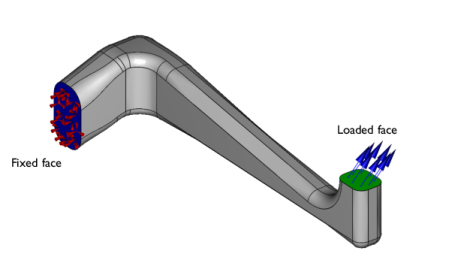

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Fixed Constraint.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Study 1 (Static)>Solver Configurations node, then click Solution 1 (sol1).

|

|

2

|

|

1

|

In the Model Builder window, expand the Results>Datasets node, then click Study 1 (Static)/Solution, Static (sol1).

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Applied Loads, Static Solution click Boundary Loads (solid).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Study 1 (Static)>Solver Configurations right-click Solution, Static (sol1) and choose Solution>Update.

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Definitions>Variables>U_max - Maximum deflection - m.

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Isosurface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>solid.mises - von Mises stress - N/m².

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Static Principal Stress Arrow Plot in the Label text field.

|

|

1

|

In the Static Principal Stress Arrow Plot toolbar, click

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Study 2 (Eigenfrequency)>Solver Configurations node, then click Solution 2 (sol2).

|

|

2

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 2 (Eigenfrequency)/Solution, Eigenfrequency (sol2).

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, expand the Results>Undamped Mode Shapes node, then click Results>Export>Animation 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Study 3 (Damped Eigenfrequency)>Solver Configurations node, then click Solution 3 (sol3).

|

|

2

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 3 (Damped Eigenfrequency)/Solution, Damped Eigenfrequency (sol3).

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, expand the Damped Mode Shapes node, then click Study 2 (Eigenfrequency)>Step 1: Eigenfrequency.

|

|

2

|

|

3

|

|

4

|

In the tree, select Component 1 (Comp1)>Solid Mechanics (Solid)>Linear Elastic Material 1>Damping 1.

|

|

5

|

Click

|