|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file tesla_microvalve_transient_optimization_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Select the Resulting objects selection check box.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the text field, type meshsz.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

In the Definitions toolbar, click

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Laminar Flow (spf) and choose Symmetry.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Global ODEs and DAEs (ge) click Global Equations 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

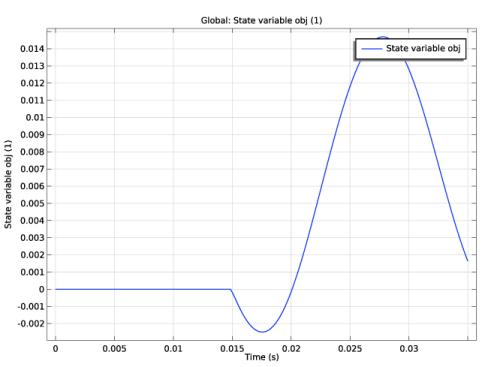

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Global ODEs and DAEs>comp1.obj - State variable obj.

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Optimization>Solver Configurations>Solution 1 (sol1) node, then click Optimization Solver 1.

|

|

2

|

|

3

|

|

4

|

In the Model Builder window, expand the Optimization>Solver Configurations>Solution 1 (sol1)>Optimization Solver 1 node, then click Time-Dependent Solver 1.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

Locate the General section. In the Variables list, choose Pressure (comp1.p), Velocity field (comp1.u), and State variable obj (comp1.ODE1).

|

|

12

|

|

13

|

In the Model Builder window, under Optimization>Solver Configurations>Solution 1 (sol1)>Optimization Solver 1>Time-Dependent Solver 1>Segregated 1 click Segregated Step 1.

|

|

14

|

|

15

|

|

16

|

In the Add dialog box, in the Variables list, choose Control material volume factor (comp1.dtopo1.theta_c), Pressure (comp1.p), and Velocity field (comp1.u).

|

|

17

|

Click OK.

|

|

18

|

In the Model Builder window, under Optimization>Solver Configurations>Solution 1 (sol1)>Optimization Solver 1>Time-Dependent Solver 1>Segregated 1 click Segregated Step 2.

|

|

19

|

|

20

|

|

21

|

In the Add dialog box, in the Variables list, choose Control material volume factor (comp1.dtopo1.theta_c) and State variable obj (comp1.ODE1).

|

|

22

|

Click OK.

|

|

23

|

|

24

|

|

25

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Topology Optimization click Output material volume factor.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Filter, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Definitions>Density Model 1>Auxiliary variables>dtopo1.theta_f - Filtered material volume factor.

|

|

3

|

|

1

|

|

2

|

Click Import.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1), Ctrl-click to select Laminar Flow (spf) and Global ODEs and DAEs (ge).

|

|

2

|

Right-click and choose Copy.

|

|

1

|

In the Model Builder window, under Component 2 (comp2), Ctrl-click to select Laminar Flow (spf2) and Global ODEs and DAEs (ge2).

|

|

2

|

|

1

|

In the Model Builder window, under Component 2 (comp2) right-click Definitions and choose Paste Domain Probe.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Laminar Flow (spf2) node, then click Symmetry 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Component 2 (comp2)>Global ODEs and DAEs (ge2) node, then click Global Equations 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Velocity (spf2), Pressure (spf2), and Objective (Verification).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|