|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Stationary.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file curve_fit_mooney_rivlin.csv.

|

|

5

|

Locate the Column Settings section. In the table, click to select the cell at row number 1 and column number 2.

|

|

7

|

|

8

|

|

10

|

|

11

|

|

12

|

|

13

|

|

15

|

|

16

|

Find the Solver settings subsection. From the Least-squares time/parameter method list, choose From least-squares objective.

|

|

17

|

|

1

|

|

2

|

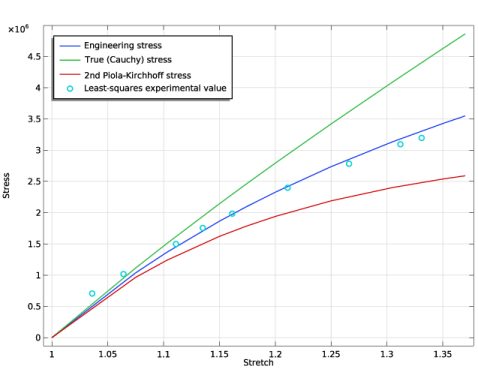

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Global definitions>Variables>P - Engineering stress - Pa.

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global, click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Solver>Parameter estimation>opt.glsobj.engStress.data - Least-squares experimental value - Pa.

|

|

3

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Stretch.

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Solver>Control parameters>C10 - Mooney-Rivlin parameter - Pa.

|

|

3

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Solver>Control parameters>C01 - Mooney-Rivlin parameter - Pa.

|

|

4

|