|

|

•

|

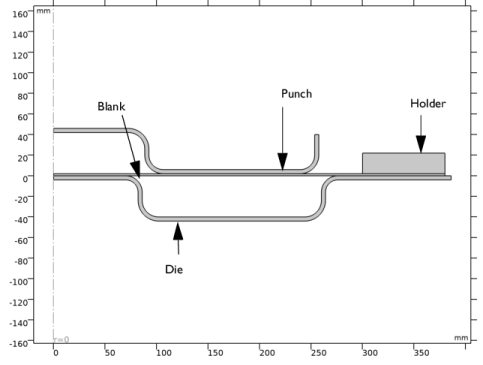

To compute the thickness of the deformed shape, a nonlocal projection coupling is used to define the variable th. Such a coupling can integrate any expression across a domain in the spatial frame. Here, integrating ‘1’ across the blank returns its deformed thickness.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3.8483E-17 m²·s4/kg²

|

|||

|

3.8483E-17 m²·s4/kg²

|

|||

|

2.6553E-17 m²·s4/kg²

|

|||

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

1

|

|

2

|

On the object pol1, select Point 3 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object fil1, select Points 3 and 5 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object fil2 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1, Ctrl-click to select Polygon 1 (pol1), Fillet 1 (fil1), Fillet 2 (fil2), and Thicken 1 (thi1).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

1

|

|

2

|

On the object pol2, select Points 3 and 5 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object fil3, select Points 3 and 5 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

Select the object fil4 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1, Ctrl-click to select Polygon 2 (pol2), Fillet 3 (fil3), Fillet 4 (fil4), and Thicken 2 (thi2).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Settings window for Interpolation, type Prescribed Punch Displacement in the Label text field.

|

|

4

|

|

6

|

|

7

|

In the Function table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

In the Function table, enter the following settings:

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

1

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the tree, select Built-in>Aluminum.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Linear Elastic Material 1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Contact Pressure Penalty Factor section. From the Penalty factor control list, choose Manual tuning.

|

|

6

|

|

7

|

|

8

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

m²·s4/kg²

|

||||

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Click the Custom button.

|

|

5

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click on Show Default Solver in order to customize the solver settings. Use a Constant (Newton) method as the nonlinear method in the Fully Coupled node. Use a Linear predictor is chosen in the Parametric node.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Fully Coupled 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 click Parametric.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Parametric and choose Stop Condition.

|

|

12

|

|

13

|

Click

|

|

15

|

|

16

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Select the Description check box.

|

|

4

|

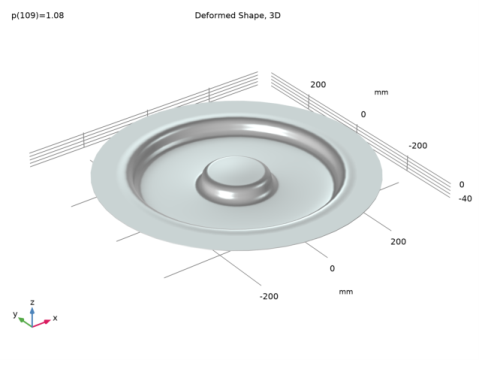

In the associated text field, type Deformed shape, 3D.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Select the Description check box.

|

|

7

|

In the associated text field, type Vertical displacement.

|

|

8

|

|

9

|