|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

In the list, select 3 (selected, meshed) (the edge located in the upper right corner of the previous image).

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Warning node, then click Component 1 (comp1)>Mesh 1>Import 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

Click the

|

|

6

|

|

8

|

|

9

|

|

10

|

|

11

|

In the Maximum hole perimeter text field, type 2.3[mm]. The value you enter here should be slightly larger than the measured hole perimeter.

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

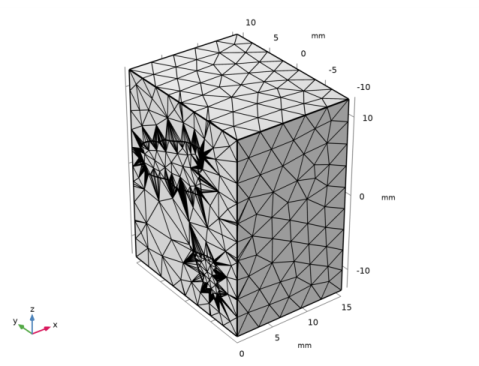

Right-click Mesh 1 and choose Import. Make sure the Import 2 node is added after Fill Holes 1 in the model tree.

|

|

3

|

|

4

|

From the Source list, choose Meshing sequence. This will automatically suggest to import Mesh 2, which is the mesh of the block.

|

|

5

|

|

6

|

Click Import.

|

|

7

|

|

8

|

Rotate the mesh in the Graphics window to check that the vertebra is fully contained in the block, the two meshes should not intersect.

|

|

9

|

|

1

|

|

2

|

Check the Messages window. Two domains were created; one for the vertebra and one for the domain of the surrounding block.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Delete Entities, click

|

|

3

|

|

4

|

|

5

|

In the Selection list, confirm that you have the expected nine boundaries; six for the block and three for the vertebra. If there are more than nine boundaries in the list, check the tolerance setting for the Intersect with plane operation.

|

|

6

|

Click the

|

|

7

|

|

8

|

|

10

|

Click the

|

|

1

|

|

2

|

Select Boundaries 2–9 only. This is most easily done from the Selection List, as some of the boundaries are hidden.

|

|

3

|

|

4

|

In the Relative simplification tolerance text field, type 0.001. The lowered tolerance allows for a closer representation of the curved parts of the vertebra faces with smaller radius.

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Expression text field, type x>1[mm] to visualize elements with at least one vertex with x-coordinate higher than 1 mm.

|

|

5

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Mesh Plot 1 toolbar, click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|