|

|

1

|

|

2

|

In the Select Physics tree, select Heat Transfer>Radiation>Heat Transfer with Radiation in Participating Media.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Global Definitions right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Radiation in Participating Media (rpm).

|

|

2

|

In the Settings window for Radiation in Participating Media, locate the Participating Media Settings section.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1), Ctrl-click to select Heat Transfer in Solids (ht) and Radiation in Participating Media (rpm).

|

|

2

|

Right-click and choose Copy.

|

|

1

|

In the Model Builder window, under Component 2 (comp2), Ctrl-click to select Heat Transfer in Solids (ht2) and Radiation in Participating Media (rpm2).

|

|

2

|

|

1

|

In the Physics toolbar, click

|

|

2

|

In the Settings window for Heat Transfer with Radiation in Participating Media, locate the Domain Selection section.

|

|

3

|

|

1

|

In the Model Builder window, under Component 2 (comp2) click Radiation in Participating Media (rpm2).

|

|

2

|

In the Settings window for Radiation in Participating Media, locate the Participating Media Settings section.

|

|

3

|

Find the Radiation settings subsection. From the Radiation discretization method list, choose P1 approximation.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Study 1: DOM, Ctrl-click to select Parametric Sweep and Step 1: Time Dependent.

|

|

2

|

Right-click and choose Copy.

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Heat Transfer in Solids (ht) and Radiation in Participating Media (rpm).

|

|

4

|

In the table, clear the Solve for check box for Heat Transfer with Radiation in Participating Media 1 (htrpm1).

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Heat Transfer in Solids (ht2) and Radiation in Participating Media (rpm2).

|

|

4

|

In the table, clear the Solve for check box for Heat Transfer with Radiation in Participating Media 2 (htrpm2).

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Import.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Optically Thick Participating Medium, locate the Optically Thick Participating Medium section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Study 2: P1, Ctrl-click to select Parametric Sweep and Step 1: Time Dependent.

|

|

2

|

Right-click and choose Copy.

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Heat Transfer in Solids (ht), Radiation in Participating Media (rpm), Heat Transfer in Solids (ht2), and Radiation in Participating Media (rpm2).

|

|

4

|

In the table, clear the Solve for check boxes for Heat Transfer with Radiation in Participating Media 1 (htrpm1) and Heat Transfer with Radiation in Participating Media 2 (htrpm2).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

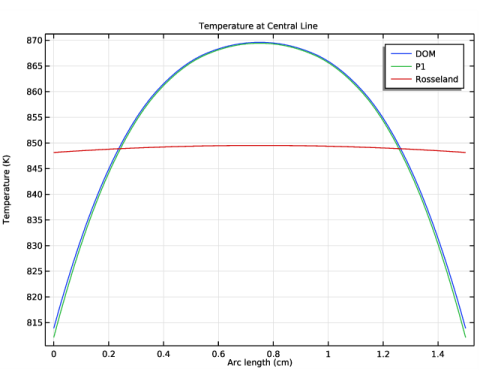

In the Settings window for 1D Plot Group, type Temperature at Central Line for k = 5 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Legends section. Click to collapse the Legends section. Click to expand the Legends section. From the Legends list, choose Manual.

|

|

7

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

In the Model Builder window, right-click Temperature at Central Line for k = 5 and choose Duplicate.

|

|

2

|

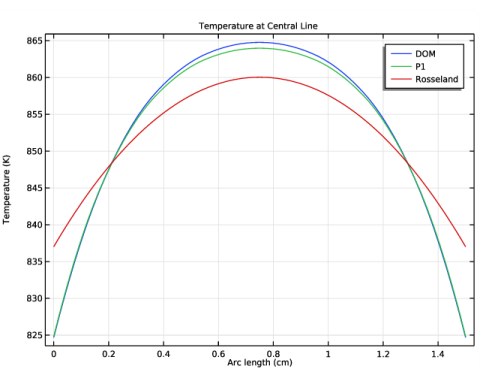

In the Settings window for 1D Plot Group, type Temperature at Central Line for k = 120 in the Label text field.

|

|

1

|

In the Model Builder window, expand the Temperature at Central Line for k = 120 node, then click Line Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|