|

|

•

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

In the Select Physics tree, select Fluid Flow>Porous Media and Subsurface Flow>Free and Porous Media Flow (fp).

|

|

5

|

Click Add.

|

|

6

|

|

7

|

In the Velocity field components table, enter the following settings:

|

|

8

|

|

9

|

In the Select Physics tree, select Fluid Flow>Porous Media and Subsurface Flow>Free and Porous Media Flow (fp).

|

|

10

|

Click Add.

|

|

11

|

|

12

|

In the Velocity field components table, enter the following settings:

|

|

13

|

|

14

|

Click

|

|

15

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Hydrogen Fuel Cell>Stationary with Initialization.

|

|

16

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file sofc_unit_cell_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Work Plane 1 (wp1) and choose Extrude.

|

|

2

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Free and Porous Media Flow, type Free and Porous Media Flow - Cathode in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Free and Porous Media Flow, type Free and Porous Media Flow - Anode in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Select the H2O check box.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the tree, select Fuel Cell and Electrolyzer>Solid Oxides>Yttria-Stabilized Zirconia, 8YSZ, (ZrO2)0.92-(Y2O3)0.08.

|

|

4

|

|

5

|

|

1

|

In the Settings window for H2 Gas Diffusion Electrode, locate the Electrode Charge Transport section.

|

|

2

|

|

3

|

Locate the Effective Electrolyte Charge Transport section. From the Effective conductivity correction list, choose User defined. In the fl text field, type fl_a.

|

|

4

|

|

1

|

|

2

|

In the Settings window for H2 Gas Diffusion Electrode Reaction, click to expand the Reference Pressures section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc) click O2 Gas Diffusion Electrode 1.

|

|

2

|

In the Settings window for O2 Gas Diffusion Electrode, locate the Electrode Charge Transport section.

|

|

3

|

|

4

|

Locate the Effective Electrolyte Charge Transport section. From the Effective conductivity correction list, choose User defined. In the fl text field, type fl_c.

|

|

5

|

|

1

|

|

2

|

In the Settings window for O2 Gas Diffusion Electrode Reaction, click to expand the Reference Pressures section.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Hydrogen Fuel Cell (fc)>H2 Gas Phase 1 node, then click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrogen Fuel Cell (fc)>O2 Gas Phase 1 click Initial Values 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Free and Porous Media Flow - Cathode (fp).

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Free and Porous Media Flow - Anode (fp2).

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

In the associated text field, type W_channel/8.

|

|

6

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

In the associated text field, type W_channel.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>Electrode kinetics>fc.ivtot - Electrode reaction source - A/m³.

|

|

6

|

|

7

|

Select the Description check box.

|

|

8

|

In the associated text field, type Average cell current density.

|

|

1

|

|

2

|

In the Settings window for Current Distribution Initialization, locate the Physics and Variables Selection section.

|

|

3

|

In the table, clear the Solve for check boxes for Reacting Flow, H2 Gas Phase 1 (rfh1) and Reacting Flow, O2 Gas Phase 1 (rfo1).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check boxes for Reacting Flow, H2 Gas Phase 1 (rfh1) and Reacting Flow, O2 Gas Phase 1 (rfo1).

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Hydrogen Fuel Cell (fc) and Free and Porous Media Flow - Anode (fp2).

|

|

4

|

In the table, clear the Solve for check boxes for Reacting Flow, H2 Gas Phase 1 (rfh1) and Reacting Flow, O2 Gas Phase 1 (rfo1).

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Hydrogen Fuel Cell (fc) and Free and Porous Media Flow - Cathode (fp).

|

|

4

|

In the table, clear the Solve for check boxes for Reacting Flow, H2 Gas Phase 1 (rfh1) and Reacting Flow, O2 Gas Phase 1 (rfo1).

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

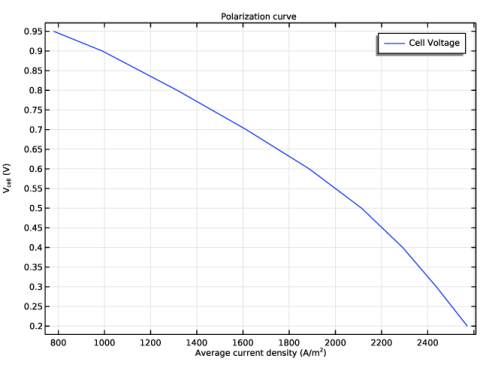

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

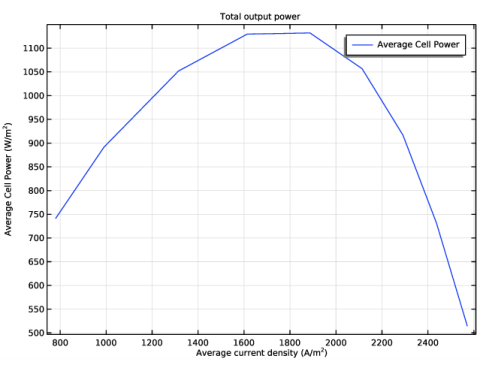

In the associated text field, type Average current density (A/m<sup>2</sup>).

|

|

7

|

|

8

|

In the associated text field, type V<sub>cell</sub> (V).

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the associated text field, type Average current density (A/m<sup>2</sup>).

|

|

7

|

|

8

|

In the associated text field, type Average Cell Power (W/m<sup>2</sup>).

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Hydrogen Fuel Cell>Electrolyte current density vector - A/m²>fc.Ilz - Electrolyte current density vector, z component.

|

|

1

|

|

3

|

|

4

|