|

|

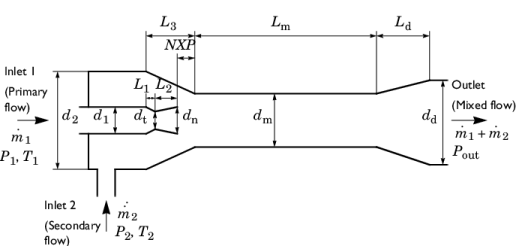

d1

|

d2

|

dt

|

dnd

|

dm

|

dd

|

|

L1

|

L2

|

L3

|

Lm

|

Ld

|

|

|

1

|

|

2

|

In the Select Physics tree, select Fluid Flow>High Mach Number Flow>Turbulent Flow>High Mach Number Flow, k-ε (hmnf).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file supersonic_ejector_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Stabilization.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for High Mach Number Flow, k-ε, click to expand the Inconsistent Stabilization section.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>High Mach Number Flow, k-ε (hmnf) click Fluid 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Specify the u vector as

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

1

|

|

2

|

|

4

|

|

5

|

Click

|

|

7

|

Click

|

|

9

|

|

10

|

|

1

|

|

2

|

|

4

|

Click to expand the Adaptation and Error Estimates section. From the Adaptation and error estimates list, choose Adaptation and error estimates.

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2>Segregated 1 node, then click Flow variables u, p, T.

|

|

4

|

|

5

|

|

6

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 2>Segregated 1 click Turbulence variables.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

In the Rename Evaluation Group dialog box, type Evaluation mass flow group in the New label text field.

|

|

4

|

Click OK.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

5

|

|

1

|

|

2

|

|

3

|

Click OK.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1/Adaptive Mesh Refinement Solutions 1 (sol3).

|

|

4

|

|

5

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1/Adaptive Mesh Refinement Solutions 1 (sol3).

|

|

4

|

|

5

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|

Click

|

|

1

|

Go to the Table window.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1/Adaptive Mesh Refinement Solutions 1 (sol3).

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1/Adaptive Mesh Refinement Solutions 1 (sol3).

|

|

4

|

|

5

|

|

6

|

|

7

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|