|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

|

7

|

Click

|

|

8

|

|

9

|

Click

|

|

1

|

|

2

|

Browse to the model’s Application Libraries folder and double-click the file jelly_roll_flattened_geom_sequence.mph.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file jelly_roll_flattened_parameters.txt.

|

|

1

|

|

2

|

In the tree, select Built-in>Aluminum.

|

|

3

|

|

4

|

In the tree, select Built-in>Copper.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, click NMC 111, LiNi0.33Mn0.33Co0.33O2 (Positive, Li-ion Battery) (mat4).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte Current Conduction section. From the σl list, choose User defined. In the associated text field, type sigmal_eff.

|

|

5

|

|

6

|

Locate the Electrode Current Conduction section. From the σs list, choose User defined. In the associated text field, type sigmas_eff.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click LiPF6 in 3:7 EC:EMC (Liquid, Li-ion Battery) (mat5).

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

|

9

|

|

11

|

|

13

|

|

15

|

|

17

|

|

19

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

8

|

|

10

|

|

12

|

|

14

|

|

16

|

|

18

|

|

20

|

|

1

|

|

2

|

In the Settings window for Electrolyte Potential, type Electrolyte Potential Coupling 1 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Electrolyte Potential, type Electrolyte Potential Coupling 2 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

7

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Continuity 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the associated text field, type H_tab_outside_jr/5.

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

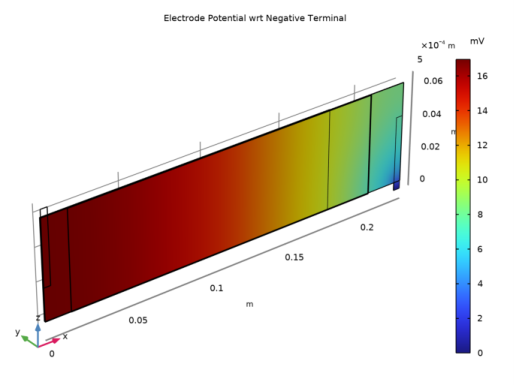

In the Settings window for 3D Plot Group, type Electrode Potential wrt Negative Terminal in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Volume, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.phis - Electric potential - V.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, right-click Electrode Potential wrt Negative Terminal and choose Duplicate.

|

|

2

|

In the Settings window for 3D Plot Group, type Electrode Potential wrt Positive Terminal in the Label text field.

|

|

1

|

In the Model Builder window, expand the Electrode Potential wrt Positive Terminal node, then click Volume 1.

|

|

2

|

In the Settings window for Volume, click Insert Expression (Ctrl+Space) in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.phis0_ec1 - Electric potential on boundary - V.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Electrolyte Current Density, Separator 1 in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Secondary Current Distribution>cd.nIl - Normal electrolyte current density - A/m².

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Settings window for 3D Plot Group, type Electrolyte Current Density, Separator 2 in the Label text field.

|

|

1

|

In the Model Builder window, expand the Results>Electrolyte Current Density, Separator 2>Surface 1 node, then click Selection 1.

|

|

2

|

|

3

|

|

4

|