|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Hydrodynamic Bearing (hdb) click Hydrodynamic Journal Bearing 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Locate the Fluid Properties section. From the μ list, choose User defined. In the associated text field, type mu0.

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

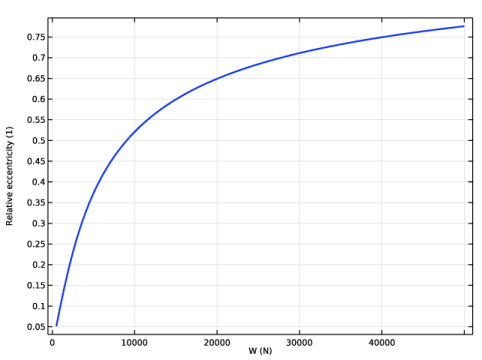

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing 1>hdb.hjb1.ec_rel - Relative eccentricity.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

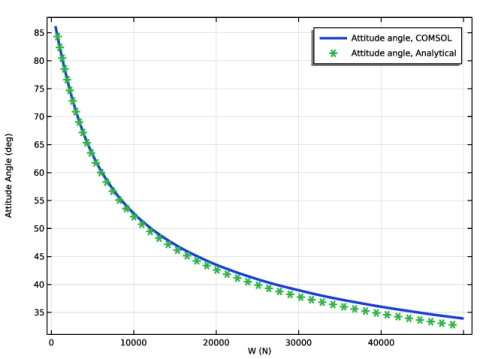

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Hydrodynamic Journal Bearing 1>hdb.hjb1.phia - Attitude angle - rad.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Attitude Angle (deg).

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

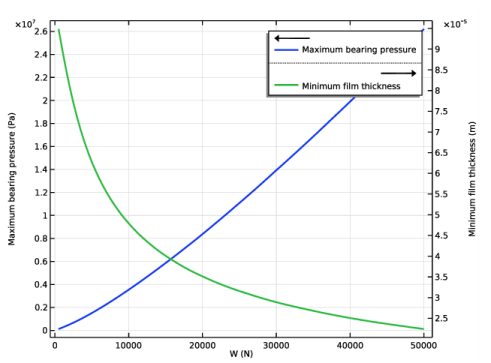

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Journal and bearing properties>hdb.hjb1.p_max - Maximum bearing pressure - Pa.

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Journal and bearing properties>hdb.hjb1.h_min - Minimum film thickness - m.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Dynamic coefficients>hdb.hjb1.k22 - Bearing stiffness, local yy component - N/m.

|

|

3

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Dynamic coefficients>hdb.hjb1.k23 - Bearing stiffness, local yz component - N/m.

|

|

4

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Dynamic coefficients>hdb.hjb1.k32 - Bearing stiffness, local zy component - N/m.

|

|

5

|

Click Add Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Dynamic coefficients>hdb.hjb1.k33 - Bearing stiffness, local zz component - N/m.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

In the associated text field, type Dimensionless Stiffness.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Hydrodynamic Bearing>Dynamic coefficients>hdb.hjb1.c22 - Bearing damping coefficient, local yy component - N·s/m.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the associated text field, type Dimensionless Damping.

|