|

|

•

|

Lumped System Connector boundary feature in the Heat Transfer in Solids interface

|

|

•

|

External Terminal feature in the Lumped Thermal System interface

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Material Link.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Material Link.

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Heat Transfer in Solids (ht) and choose Temperature.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

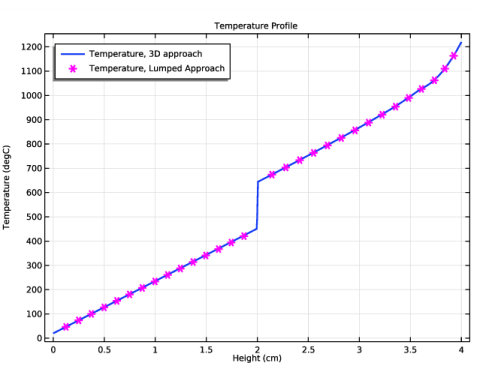

In the associated text field, type Height (cm).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

11

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Study 1.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve check box for Heat Transfer in Solids (ht).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

Locate the Component Parameters section. From the Specify list, choose Thermal and geometric properties.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

14

|

|

15

|

|

16

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

12

|