|

|

1

|

|

2

|

Click

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file printed_circuit_board_si_geom.zip.

|

|

5

|

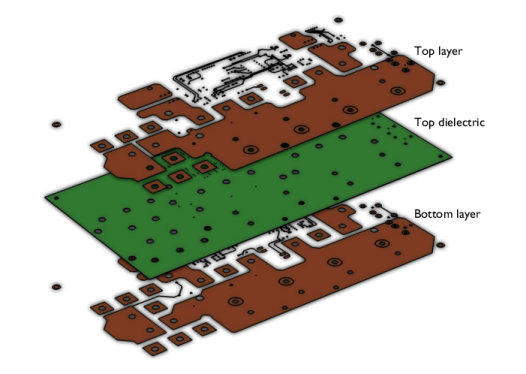

Find the Layers to import subsection. In the table, select to import only the following layers:

|

|

6

|

|

7

|

|

8

|

Click Import.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose TOP (Import 1), BOTTOM (Import 1), and TOP.DIEL (Import 1).

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Add dialog box, in the Selections to add list, choose TOP (Import 1), BOTTOM (Import 1), and DRILL.TOP.DIEL (Import 1).

|

|

6

|

Click OK.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the tree, select Built-in>Copper.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

In the list, select 317.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

In the list, select 237.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

In the associated text field, type 0.1[in].

|

|

8

|

|

9

|

In the associated text field, type 0.01[in].

|

|

10

|

|

11

|