|

|

1

|

|

2

|

In the Select Physics tree, select Electrochemistry>Primary and Secondary Current Distribution>Secondary Current Distribution (cd).

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

7

|

|

8

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file localized_corrosion_ls_microstructure.txt.

|

|

6

|

Click Import.

|

|

7

|

Find the Functions subsection. In the table, enter the following settings:

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

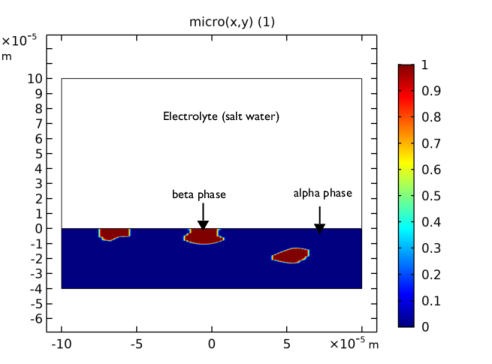

In the Rename 2D Plot Group dialog box, type 2D Plot Group : Cross-sectional microstructure in the New label text field.

|

|

3

|

Click OK.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file localized_corrosion_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file localized_corrosion_i_alpha.txt.

|

|

6

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

7

|

|

8

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file localized_corrosion_i_beta.txt.

|

|

6

|

Locate the Interpolation and Extrapolation section. From the Interpolation list, choose Piecewise cubic.

|

|

7

|

|

8

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both domains.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file localized_corrosion_ls_variables.txt.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Secondary Current Distribution (cd) click Electrolyte 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both domains.

|

|

3

|

In the Settings window for Electrolyte Current Source, locate the Electrolyte Current Source section.

|

|

4

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select both domains.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

1

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Edit Physics-Induced Sequence.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

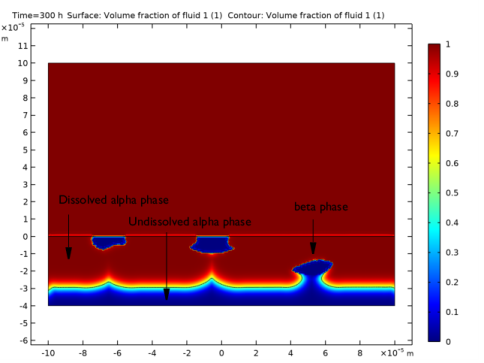

In the Model Builder window, expand the Volume Fraction of Fluid 1 (ls) node, then click Volume Fraction of Fluid 1.1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|