|

|

•

|

Two negative porous electrodes (60 μm thick)

|

|

•

|

Two positive porous electrodes (60 μm thick)

|

|

•

|

One negative current collector (14 μm thick)

|

|

•

|

One positive current collector (20 μm thick)

|

|

•

|

Two separator regions (30 μm thick)

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time Dependent with Initialization.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file li_battery_spiral_2d_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Click in the Graphics window and then press Ctrl+A to select all objects.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Positive current collector, Negative current collector, Positive porous electrode, Negative porous electrode, and Electrolyte.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Add dialog box, in the Selections to add list, choose Positive porous electrode, Negative porous electrode, Electrolyte, and Electrolyte outside.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Aluminum.

|

|

4

|

|

5

|

In the tree, select Built-in>Copper.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the tree, select Battery>Electrolytes>LiPF6 in 1:2 EC:DMC and p(VdF-HFP) (Polymer electrolyte, Li-ion Battery).

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials click LiPF6 in 1:2 EC:DMC and p(VdF-HFP) (Polymer electrolyte, Li-ion Battery) (mat3).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Lithium-Ion Battery (liion) and choose Porous Electrode.

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Properties section. From the Electrode material list, choose Graphite Electrode, LixC6 MCMB (Negative, Li-ion Battery) (mat4).

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Porous Electrode 1 node, then click Particle Intercalation 1.

|

|

2

|

|

3

|

From the Particle material list, choose Graphite Electrode, LixC6 MCMB (Negative, Li-ion Battery) (mat4).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrode Properties section. From the Electrode material list, choose LMO Electrode, LiMn2O4 Spinel (Positive, Li-ion Battery) (mat5).

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Porous Electrode 2 node, then click Particle Intercalation 1.

|

|

2

|

|

3

|

From the Particle material list, choose LMO Electrode, LiMn2O4 Spinel (Positive, Li-ion Battery) (mat5).

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Electrode Current Density, type Electrode Current Density - 1C Discharge in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Electrode Current Density, type Electrode Current Density - 10C Discharge in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Relative placement of vertices along edge text field, type 0 5e-5 10^range(-4,0.25,-2) range(2e-2,1e-2,0.98) (1-10^range(-2,-0.25,-4)) 0.99995 1.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Lithium-Ion Battery>phis - Electric potential - V.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

In the Physics and variables selection tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current Density - 10C Discharge.

|

|

6

|

Click

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

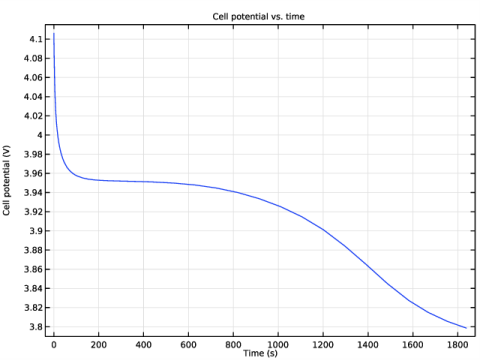

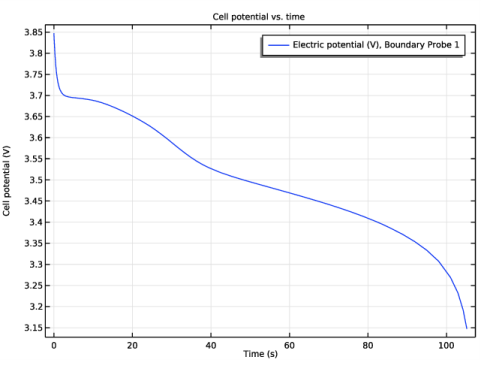

In the associated text field, type Cell potential (V).

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Relative Li Concentration at Surface of Negative Electrode Particles in the Label text field.

|

|

3

|

|

4

|

Locate the Data section. From the Dataset list, choose Study 1 - 1 C Discharge/Solution 1 (4) (sol1).

|

|

1

|

Right-click Relative Li Concentration at Surface of Negative Electrode Particles and choose Surface.

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Lithium-Ion Battery>Particle intercalation>liion.socloc_surface - Local electrode material state-of-charge, particle surface.

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Relative Li Concentration at Surface of Positive Electrode Particles in the Label text field.

|

|

3

|

Locate the Data section. From the Dataset list, choose Study 1 - 1 C Discharge/Solution 1 (5) (sol1).

|

|

4

|

|

1

|

Right-click Relative Li Concentration at Surface of Positive Electrode Particles and choose Surface.

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Lithium-Ion Battery>Particle intercalation>liion.socloc_surface - Local electrode material state-of-charge, particle surface.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Time Dependent with Initialization.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

In the Physics and variables selection tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current Density - 1C Discharge.

|

|

6

|

Click

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 1 - 1 C Discharge/Solution 1 (4) (sol1).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 1 - 1 C Discharge/Solution 1 (5) (sol1).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, click Relative Li Concentration at Surface of Negative Electrode Particles.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, click Relative Li Concentration at Surface of Positive Electrode Particles.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

4

|

In the Physics and variables selection tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current Density - 1C Discharge.

|

|

5

|

Click

|

|

6

|

In the Physics and variables selection tree, select Component 1 (comp1)>Lithium-Ion Battery (liion)>Electrode Current Density - 10C Discharge.

|

|

7

|

Click

|

|

8

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

9

|

|

10

|

|

11

|

|

12

|

In the Settings window for Study, type Study 3 - Relaxation after 1C Discharge in the Label text field.

|

|

13

|

|

14

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 2 - 10 C Discharge/Solution 3 (4) (sol3).

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets click Study 2 - 10 C Discharge/Solution 3 (5) (sol3).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, click Relative Li Concentration at Surface of Negative Electrode Particles.

|

|

2

|

|

3

|

Click

|

|

1

|

In the Model Builder window, click Relative Li Concentration at Surface of Positive Electrode Particles.

|

|

2

|

|

3

|