|

|

1

|

|

2

|

In the Select Physics tree, select Acoustics>Acoustic-Structure Interaction>Acoustic-Shell Interaction, Frequency Domain.

|

|

3

|

Click Add.

|

|

4

|

Click Study.

|

|

5

|

|

6

|

Click Done.

|

|

1

|

|

2

|

|

3

|

Click Browse.

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file vented_loudspeaker_enclosure.mphbin.

|

|

5

|

Click Import.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file vented_loudspeaker_enclosure_Rb.txt.

|

|

6

|

Click Import.

|

|

7

|

|

8

|

|

9

|

|

10

|

Locate the Interpolation and Extrapolation section. From the Extrapolation list, choose Nearest function.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Browse.

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file vented_loudspeaker_enclosure_Lb.txt.

|

|

6

|

Click Import.

|

|

7

|

|

8

|

|

9

|

|

10

|

Locate the Interpolation and Extrapolation section. From the Extrapolation list, choose Nearest function.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Pressure Acoustics, Frequency Domain (acpr).

|

|

2

|

In the Settings window for Pressure Acoustics, Frequency Domain, locate the Domain Selection section.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the tree, select Built-in>Air.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Geometric entity level list, choose Boundary.

|

|

4

|

|

5

|

|

1

|

|

2

|

In the tree, select Built-in>Copper.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Pressure Acoustics, Frequency Domain (acpr) and choose Symmetry.

|

|

1

|

|

1

|

|

3

|

In the Settings window for Exterior Field Calculation, locate the Exterior Field Calculation section.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Mesh 1 and choose Boundary Layers.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node.

|

|

4

|

Right-click Suggested Iterative Solver (GMRES with GMG and Direct Precon.) (asb1) and choose Enable.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1>Shell>Displacement>shell.disp - Total displacement - m.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Geometry>dom - Entity index.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Locate the Title section. In the Title text area, type Sound Pressure Level (dB), f=eval(freq,Hz) Hz.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Slice, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1>Pressure Acoustics, Frequency Domain>Pressure and sound pressure level>acpr.Lp - Sound pressure level - dB.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

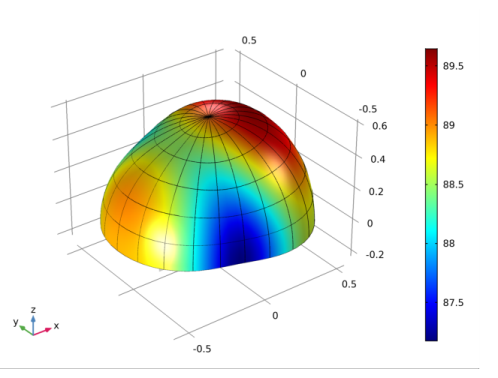

In the Settings window for 3D Plot Group, type Exterior-Field Sound Pressure Level in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Evaluation section. Find the Angles subsection. In the Number of elevation angles text field, type 30.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, right-click Exterior-Field Sound Pressure Level and choose Paste Volume.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

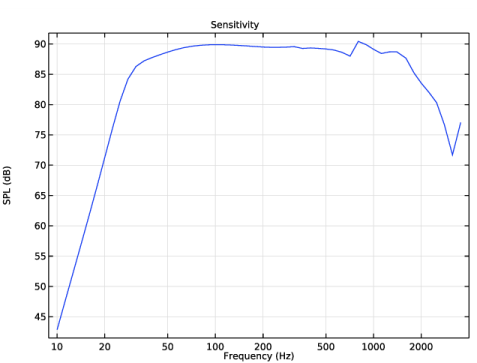

In the associated text field, type Frequency (Hz).

|

|

7

|

|

8

|

In the associated text field, type SPL (dB).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|