|

•

|

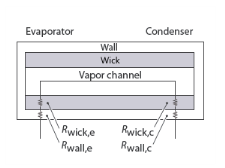

Rwall,e the thermal resistance of the wall on evaporator side

|

|

•

|

Rwick,e the thermal resistance of the wick on evaporator side

|

|

•

|

Rlv,e the thermal resistance of the liquid-vapor interface on evaporator side

|

|

•

|

Rlv,c the thermal resistance of the liquid-vapor interface on condenser side

|

|

•

|

Rwick,c the thermal resistance of the wick on condenser side

|

|

•

|

Rwall,c the thermal resistance of the wall on condenser side

|

|

•

|

Rv,a the thermal resistance of the vapor channel in adiabatic section

|

|

•

|

Rwick,a the thermal resistance of the wick in adiabatic section

|

|

•

|

Rwall,a the thermal resistance of the wall in adiabatic section

|