You are viewing the documentation for an older COMSOL version. The latest version is

available here.

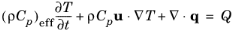

(6-11)

(6-12)

|

•

|

ρ (SI unit: kg/m 3) is the fluid density.

|

|

•

|

Cp (SI unit: J/(kg·K)) is the fluid heat capacity at constant pressure.

|

|

•

|

(ρCp)eff (SI unit: J/(m 3·K)) is the effective volumetric heat capacity at constant pressure defined by an averaging model to account for both solid matrix and fluid properties.

|

|

•

|

q is the conductive heat flux (SI unit: W/m 2).

|

|

•

|

u (SI unit: m/s) is the fluid velocity field, either an analytic expression or the velocity field from a Fluid Flow interface. u should be interpreted as the Darcy velocity, that is, the volume flow rate per unit cross sectional area. The average linear velocity (the velocity within the pores) can be calculated as uL = u ⁄ θL, where θL is the fluid’s volume fraction, or equivalently the porosity.

|

|

•

|

keff (SI unit: W/(m·K)) is the effective thermal conductivity (a scalar or a tensor if the thermal conductivity is anisotropic), defined by an averaging model to account for both solid matrix and fluid properties.

|

|

•

|

Q (SI unit: W/m 3) is the heat source (or sink). Add one or several heat sources as separate physics features. See Heat Source node and Viscous Dissipation subnode for example.

|

This section is available when a temperature-dependent density defined in a material is used. On the material frame, the density is evaluated onto a reference temperature to ensure mass conservation in the presence of temperature variations. By default the Common model input is used. This corresponds to the variable

minput.Tempref, which is set by default to 293.15 K. To edit it, click the

Go to Source button (

), and in the

Default Model Inputs node under

Global Definitions, set a value for the

Volume reference temperature in the

Expression for remaining selection section.

The other options are User defined and all temperature variables from the physics interfaces included in the model.

|

|

This model input does not override the Reference temperature Tref set in the Physical Model section of the physics interface, and that is used to evaluate the reference enthalpy, and a reference density for incompressible nonisothermal flows.

|

This section is available when temperature-dependent material properties are used. By default the temperature of the parent interface is used and the section is not editable. To edit the Temperature field, click

Make All Model Inputs Editable (

). The available options are

User defined (default),

Common model input (the

minput.T variable, set to 293.15 K by default) and all temperature variables from the physics interfaces included in the model. To edit the

minput.T variable, click the

Go to Source button (

), and in the

Default Model Inputs node under

Global Definitions, set a value for the

Temperature in the

Expression for remaining selection section.

The default Absolute pressure pA is taken from

Common model input. It corresponds to the

minput.pA variable, set to 1 atm by default. To edit it, click the

Go to Source button (

), and in the

Default Model Inputs node under

Global Definitions, set a value for the

Pressure in the

Expression for remaining selection section. When additional physics interfaces are added to the model, the absolute pressure variables defined by these physics interfaces can also be selected from the list. For example, if a

Laminar Flow interface is added you can select

Absolute pressure (spf) from the list. The last option is

User defined.

From the Concentration c (SI unit: mol/m

3 or kg/m

3) list, select an existing concentration variable from another physics interface, if any concentration variables exist,

User defined to enter a value or expression for the concentration, or

Common model input which corresponds to the

minput.c variable.

Select any component material from the list to define the Fluid material. The default uses the

Domain material. It makes it possible to define different material properties for the fluid phase when the domain material corresponds to the solid phase (porous matrix) material.

The default Velocity field u is

User defined. For

User defined enter values or expressions for the components based on space dimensions. Or select an existing velocity field in the component (for example,

Velocity field (spf) from a

Laminar Flow interface). The

Common model input option corresponds to the

minput.u variable. To edit it, click the

Go to Source button (

), and in the

Default Model Inputs node under

Global Definitions, set values for the

Velocity components in the

Expression for remaining selection section.

The thermal conductivity k describes the relationship between the heat flux vector

q and the temperature gradient

∇T in

q = −k∇T, which is Fourier’s law of heat conduction. Enter this quantity as power per length and temperature.

The default Thermal conductivity k is taken

From material. For

User defined select

Isotropic,

Diagonal,

Symmetric, or

Full based on the characteristics of the thermal conductivity, and enter another value or expression. For

Isotropic enter a scalar which will be used to define a diagonal tensor. For the other options, enter values or expressions into the editable fields of the tensor.

The heat capacity at constant pressure Cp describes the amount of heat energy required to produce a unit temperature change in a unit mass.

The ratio of specific heats γ is the ratio of the heat capacity at constant pressure,

Cp, to the heat capacity at constant volume,

Cv. When using the ideal gas law to describe a fluid, specifying

γ is sufficient to evaluate

Cp. For common diatomic gases such as air,

γ = 1.4 is the standard value. Most liquids have

γ = 1.1 while water has

γ = 1.0. γ is used in the streamline stabilization and in the variables for heat fluxes and total energy fluxes. It is also used if the ideal gas law is applied.

The available Fluid type options are

Gas/Liquid (default),

Moist air, or

Ideal gas. After selecting a

Fluid type from the list, further settings display underneath.

This option specifies the Density, the

Heat capacity at constant pressure, and the

Ratio of specific heats for a general gas or liquid.

|

•

|

The gas constant, with two options for the Gas constant type: Specific gas constant Rs or Mean molar mass Mn. If Mean molar mass is selected the software uses the universal gas constant R = 8.314 J/(mol·K), which is a built-in physical constant, to compute the specific gas constant.

|

|

•

|

Either the Heat capacity at constant pressure Cp or Ratio of specific heats γ by selecting the option from the Specify Cp or γ list. For an ideal gas, it is sufficient to specify either Cp or the ratio of specific heats, γ, as these properties are interdependent.

|

If Moist air is selected, the thermodynamics properties are defined as a function of the quantity of vapor in the moist air. The available

Input quantity options to define the amount of vapor in the moist air are the following:

|

•

|

Concentration to define the amount of water vapor in the total volume. If selected, a Concentration model input is automatically added in the Model Inputs section.

|

|

•

|

Moisture content (also called mixing ratio or humidity ratio) to define the ratio of the water vapor mass to the dry air mass.

|

|

•

|

Relative humidity  , a quantity defined between 0 and 1, where 0 corresponds to dry air and 1 to a water vapor-saturated air. The Relative humidity, temperature condition  and Relative humidity, absolute pressure condition  must be specified.

|

If the Standard porous matrix model is selected under

Physical Model, select any component material in the

Solid material list. The

Volume fraction θp for the solid material should be specified. For

User defined, enter a value or expression. Or select an existing volume fraction in the component (for example,

Volume fraction (dl/dlm1) from a

Darcy’s Law interface).

If the Extended porous matrix model is selected under

Physical Model (with the Subsurface Flow Module), the

Number of solids can be set from

1 to

5. Then for each solid a

Solid material list and a

Volume fraction field display underneath.

The thermal conductivity kp describes the relationship between the heat flux vector

q and the temperature gradient

∇T in

q = −kp∇T, which is Fourier’s law of heat conduction. Enter this quantity as power per length and temperature.

The default Thermal conductivity kp is taken

From material. For

User defined select

Isotropic,

Diagonal,

Symmetric, or

Full based on the characteristics of the thermal conductivity, and enter another value or expression. For

Isotropic enter a scalar which will be used to define a diagonal tensor. For the other options, enter values or expressions into the editable fields of the tensor.

When the Extended porous matrix model is selected under

Physical Model (with the Subsurface Flow Module), and more than one solid is selected in the

Immobile Solids section, the thermal conductivities

kpi should be specified for each immobile solid. The average property for the porous matrix is given by:

The Density ρp and the

Specific heat capacity Cp, p should be specified. For

From Material option, see

Material Density in Features Defined in the Material Frame if a temperature-dependent density should be set.

When the Extended porous matrix model is selected under

Physical Model (with the Subsurface Flow Module), and more than one solid is selected in the

Immobile Solids section, the

Density and

Specific heat capacity should be specified for each immobile solid.

This section sets the averaging model for the computation of the Effective conductivity by accounting for both solid matrix and fluid properties. The following options are available with either the Subsurface Flow Module or the Heat Transfer Module:

|

•

|

Volume average (default), which computes the effective conductivity of the solid-fluid system as the weighted arithmetic mean of fluid and porous matrix conductivities:

|

|

•

|

Reciprocal average, which computes the effective conductivity of the solid-fluid system as the weighted harmonic mean of fluid and porous matrix conductivities:

|

|

•

|

Power law, which computes the effective conductivity of the solid-fluid system as the weighted geometric mean of fluid and porous matrix conductivities:

|

When the Extended porous matrix model is selected under

Physical Model (with the Subsurface Flow Module), and more than one solid is selected in the

Immobile Solids section, these averaging models are modified in the following way:

More locations are available if the Heat transfer in porous media check box is selected under the

Physical Model section. For example:

Physics Tab with interface as

Heat Transfer in Solids and Fluids,

Heat Transfer in Solids,

Heat Transfer in Fluids,

Heat Transfer in Porous Media,

Heat Transfer in Building Materials or

Bioheat Transfer selected: