|

•

|

<phys>.Wstb, a field showing the stabilization energy density. Its interpretation depends on the stabilization method used.

|

|

•

|

<phys>.Wstbavg, a mesh element average of the variable <phys>.Wstb. This variable is not available for layered shell features.

|

|

•

|

<phys>.Wstb_tot, the total amount of stabilization energy in the model.

|

|

•

|

The multiplier fstb is a user-defined expression of any parameter or variable in the model. It defaults to 1.

|

|

•

|

The multiplier fin is internal and used to account for various inelastic deformations like plasticity and damage.

|

|

•

|

|

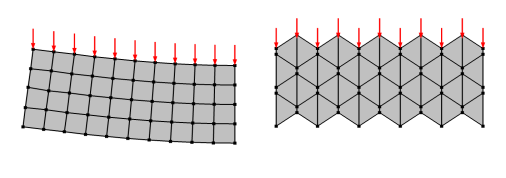

See also Reduced Integration and Hourglass Stabilization in the Structural Mechanics Theory chapter.

|