|

|

•

|

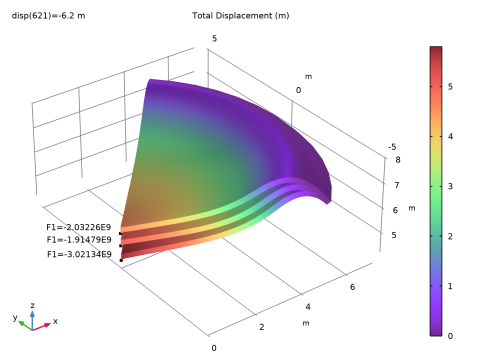

The radius of the spherical cap is a = 10 m and the thickness is th = 0.20384 m. The sector angle of the spherical cap is π/4 radians.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

9

|

Click

|

|

1

|

|

2

|

On the object c1, select Boundaries 1 and 2 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

In the Show More Options dialog, in the tree, select the checkbox for the node Physics > Equation-Based Contributions.

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

Click

|

|

10

|

|

11

|

|

12

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

In the Model Builder window, under Component 1 (comp1) > Shell (shell) click Thickness and Offset 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

Click

|

|

10

|

|

11

|

|

12

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

Click

|

|

1

|

|

2

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

Go to the Add Study window.

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve checkbox for Shell (shell).

|

|

5

|

Click the Add Study button in the window toolbar.

|

|

6

|

|

1

|

|

2

|

|

3

|

Select the Include geometric nonlinearity checkbox.

|

|

4

|

Click to expand the Mesh Selection section. In the table, enter the following settings:

|

|

5

|

|

6

|

Click

|

|

8

|

|

1

|

|

2

|

Go to the Add Study window.

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve checkbox for Solid Mechanics (solid).

|

|

5

|

Click the Add Study button in the window toolbar.

|

|

6

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

Select the Include geometric nonlinearity checkbox.

|

|

4

|

|

5

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Total Displacement, 3D (solid) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click to expand the Advanced section. Locate the Coloring and Style section. From the Anchor point list, choose Lower right.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Total Displacement, 3D (shell) in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

Go to the Result Templates window.

|

|

3

|

In the tree, select Study: Shell/Parametric Solutions 1 (sol3) > Shell > Thickness and Orientation (shell).

|

|

4

|

Click the Add Result Template button in the window toolbar.

|

|

5

|

|

1

|

In the Model Builder window, expand the Thickness and Orientation (shell) node, then click Shell Local System.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Load vs. Displacement at Crown in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Load vs. Displacement at Crown in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Point Evaluation, type Solid Mechanics, 40 Elements in the Label text field.

|

|

3

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

In the Model Builder window, right-click Load vs. Displacement at Crown and choose Point Evaluation.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

7

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|