|

|

1

|

|

2

|

In the Application Libraries window, select Porous Media Flow Module > Fluid Flow > pore_scale_flow_3d in the tree.

|

|

3

|

Click

|

|

1

|

|

1

|

In the Model Builder window, expand the Results > Tables node, then click Global Definitions > Parameters 1.

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1) > Creeping Flow (spf) node, then click Fluid Properties 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Global Definitions > Materials node, then click Material 1 (mat1).

|

|

2

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1) > Definitions node, then click Variables 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

From the list, choose Pressure.

|

|

4

|

Locate the Pressure Conditions section. Click to select the p0 text field. Right-click and choose Create Parameter.

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

Go to the Add Study window.

|

|

3

|

|

4

|

Click the Add Study button in the window toolbar.

|

|

5

|

|

1

|

|

2

|

Select the Auxiliary sweep checkbox.

|

|

3

|

Click

|

|

6

|

|

7

|

|

8

|

Clear the Generate default plots checkbox.

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Expressions section. In the table, enter the following settings:

|

|

5

|

|

1

|

Go to the Table 2 window.

|

|

2

|

Click the Table Graph button in the window toolbar.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Apparent Shear Rate vs. Normalized Velocity in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Data Column Settings section. In the table, enter the following settings:

|

|

6

|

|

7

|

Locate the Data Column Settings section. In the table, click to select the cell at row number 3 and column number 3.

|

|

8

|

|

9

|

Locate the Parameters section. In the table, enter the following settings:

|

|

10

|

Click

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

Go to the Add Physics window.

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve checkboxes for Study 1 and Study 2.

|

|

5

|

Click the Add to Component 2 button in the window toolbar.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 2 (comp2) right-click Materials and choose More Materials > Material Link.

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

From the list, choose Pressure.

|

|

5

|

|

1

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

Go to the Add Study window.

|

|

3

|

|

4

|

Find the Physics interfaces in study subsection. In the table, clear the Solve checkbox for Creeping Flow (spf).

|

|

5

|

Click the Add Study button in the window toolbar.

|

|

6

|

|

1

|

|

2

|

Select the Auxiliary sweep checkbox.

|

|

3

|

Click

|

|

5

|

|

6

|

|

7

|

Clear the Generate default plots checkbox.

|

|

8

|

|

1

|

In the Model Builder window, under Results > Derived Values right-click Global Evaluation 2 and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results > Apparent Shear Rate vs. Normalized Velocity right-click Table Graph 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, right-click Apparent Shear Rate vs. Normalized Velocity and choose Duplicate.

|

|

2

|

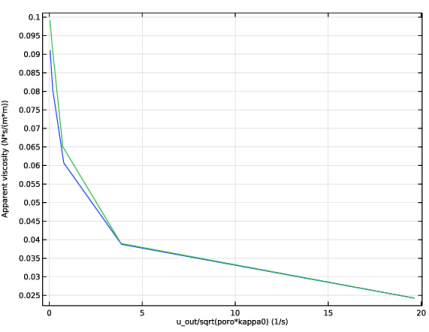

In the Settings window for 1D Plot Group, type Apparent Viscosity vs. Normalized Velocity in the Label text field.

|

|

1

|

In the Model Builder window, expand the Apparent Viscosity vs. Normalized Velocity node, then click Table Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|