|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file stray_current_train_parameters.txt.

|

|

1

|

|

2

|

In the Settings window for Gaussian Pulse, type Gaussian Pulse - Shape Train Positioning in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Interpolation - Train Propulsion Current in the Label text field.

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file stray_current_train_propulsion_current.txt.

|

|

6

|

|

7

|

In the Argument table, enter the following settings:

|

|

1

|

|

2

|

In the Settings window for Interpolation, type Interpolation - Train Location in the Label text field.

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file stray_current_train_location.txt.

|

|

6

|

|

7

|

In the Argument table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file stray_current_train_geometry.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

5

|

|

6

|

|

7

|

|

8

|

Clear the Automatic detection of small details checkbox.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

Go to the Add Material window.

|

|

3

|

|

4

|

Click the Add to Component button in the window toolbar.

|

|

5

|

|

1

|

|

2

|

Locate the Electrolyte section. From the σl list, choose User defined. In the associated text field, type 1/rho_clay.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte section. From the σl list, choose User defined. In the associated text field, type 1/rho_pond.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte section. From the σl list, choose User defined. In the associated text field, type 1/rho_sand.

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte section. From the σl list, choose User defined. From the list, choose Diagonal.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Electrolyte section. From the σl list, choose User defined. In the associated text field, type 1/rho_gravel.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Film Resistance section. From the Film resistance list, choose Surface resistance.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Electrode Current, type Electrode Current - TSS 1 in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Electric Potential, type Electric Potential - TSS 2 in the Label text field.

|

|

3

|

|

1

|

|

2

|

In the Settings window for External Current Source, type External Current Source - Train in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Electric Potential section. From the Electric potential model list, choose Floating potential.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Material Contents section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Element Size Parameters section.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Element Size Parameters section.

|

|

7

|

|

8

|

|

9

|

|

10

|

Click

|

|

1

|

|

2

|

|

3

|

Click

|

|

5

|

Click

|

|

Ω*m

|

|

1

|

|

2

|

|

3

|

Select the Auxiliary sweep checkbox.

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

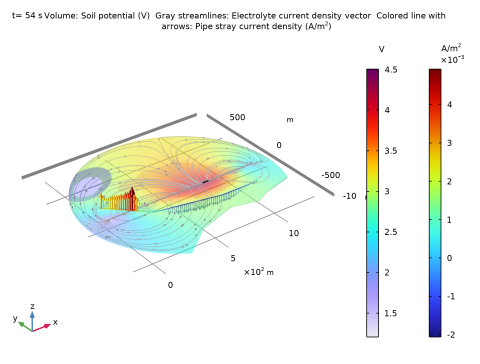

In the Settings window for 3D Plot Group, type Potential and Current Density Distribution (cp) in the Label text field.

|

|

3

|

|

4

|

|

5

|

In the Title text area, type Volume: Soil potential (V) Gray streamlines: Electrolyte current density vector Colored line with arrows: Pipe stray current density (A/m<sup>2</sup>).

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Clear the Rounded end caps checkbox.

|

|

6

|

|

7

|

|

8

|

|

9

|

Clear the Color legend checkbox.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Define custom colors.

|

|

7

|

Click Add to custom colors.

|

|

8

|

|

1

|

|

2

|

|

3

|

Click to select the

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

Click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1) > Cathodic Protection > Electrode kinetics > cp.iloc_er1 - Local current density - A/m².

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Coloring and Style section.

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1) > Cathodic Protection > Electrode kinetics > cp.iloc_er1 - Local current density - A/m².

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Coloring and Style section. Find the Point style subsection. From the Type list, choose Arrow.

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

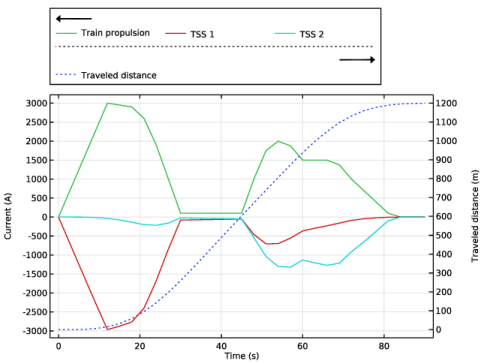

Select the Secondary y-axis label checkbox. In the associated text field, type Traveled distance (m).

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

Select the Plot on secondary y-axis checkbox.

|

|

4

|

Locate the y-Axis Data section. In the table, enter the following settings:

|

|

5

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Dotted.

|

|

6

|

|

1

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Plot Settings section.

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

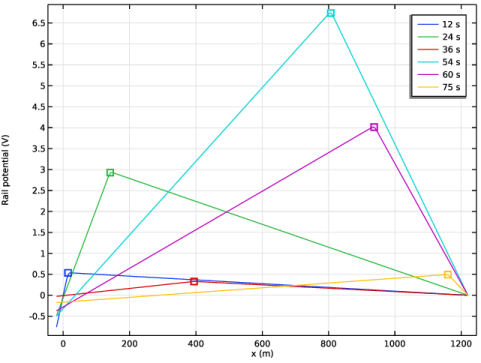

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1) > Cathodic Protection > Secondary Current Distribution (Edge electrode) > cp.phis_edge - Electric potential - V.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose None.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

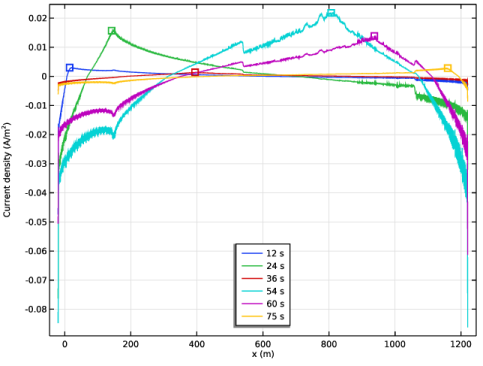

In the Settings window for 1D Plot Group, type Stray Current Density at Rail in the Label text field.

|

|

3

|

Locate the Plot Settings section. In the y-axis label text field, type Current density (A/m<sup>2</sup>).

|

|

4

|

|

1

|

In the Model Builder window, expand the Stray Current Density at Rail node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1) > Cathodic Protection > Electrode kinetics > cp.iloc_er1 - Local current density - A/m².

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

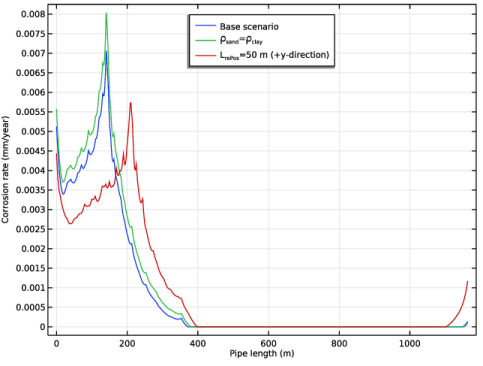

|

In the Settings window for 1D Plot Group, type Comparison - Corrosion Rate on Pipe at 54 s in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Comparison - Corrosion Rate on Pipe at 54 s node, then click Line Graph 1.

|

|

2

|

In the Settings window for Line Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1) > Definitions > Variables > dr_rate - Corrosion rate on pipe - m/s.

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Electrolyte Potential (cp) and Electrode Potential vs. Adjacent Reference (cp).

|

|

2

|

Right-click and choose Delete.

|

|

1

|

|

2

|

|

3

|