You are viewing the documentation for an older COMSOL version. The latest version is

available here.

The Laminar Flow interfaces provide various predefined inelastic non-Newtonian constitutive models including Power law, Carreau, Carreau–Yasuda, Cross, Cross–Williamson, Sisko, Bingham–Papanastasiou, Herschel–Bulkley–Papanastasiou, Casson–Papanastasiou, DeKee–Turcotte–Papanastasiou, Robertson–Stiff–Papanastasiou, Ellis, and Houska thixotropy.

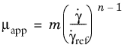

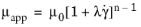

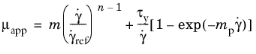

(3-13)

where m,

n are scalars that can be set to arbitrary values and

denotes a reference shear rate for which the default value is 1 s

−1. For

n > 1, the power law describes a shear thickening (dilatant) fluid. For

n < 1, it describes a shear thinning (pseudoplastic) fluid. A value of

n equal to one gives the expression for a

Newtonian fluid.

Equation 3-13 predicts an infinite viscosity at zero shear rate for

n < 1. This is however never the case physically. Instead, most fluids have a constant viscosity for shear rates smaller than 10

−2 s

−1 (

Ref. 17). Since infinite viscosity also makes models using

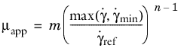

Equation 3-13 difficult to solve, COMSOL Multiphysics implements the Power law model as

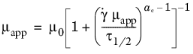

(3-14)

(3-15)

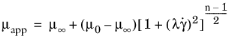

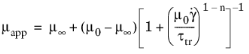

where λ is a parameter with the unit of time,

μ0 is the zero shear rate viscosity,

μ∞ is the infinite shear-rate viscosity, and

n is a dimensionless parameter. This expression is able to describe the viscosity for most stationary polymer flows.

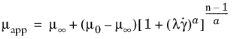

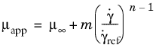

The Carreau–Yasuda model is a generalized version of the Carreau model with the transition parameter a which allows for modifying the stiffness of the transition from constant

μ0 to thinning. So, it has five parameters in the expression:

(3-16)

The Cross model is a special case of the Carreau–Yasuda model with a = 1 − n and

λ = μ0/τtr where

τtr is the critical stress. So, it has the following form:

(3-17)

(3-18)

(3-19)

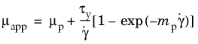

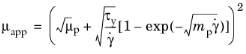

Viscoplastic fluid behavior is characterized by existence of the yield stress τy — a limit which must be exceeded before significant deformation can occur. To model the stress-deformation behavior of viscoplastic materials, different constitutive equations have been propose. The Bingham plastic model is written as

where μp is the plastic viscosity.

(3-20)

where mp is a scale that controls the exponential growth of stress.

(3-21)

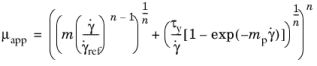

where m,

n are scalars that can be set to arbitrary values, and

is the reference shear rate. In case

n equals one, the Bingham–Papanastasiou model is recovered. This equation is valid in both yielded and unyielded regions. The exponent

mp controls the smoothness of the viscosity function.

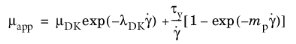

(3-22)

(3-23)

where μDK and

λDK denote the shear rate viscosity and relaxation time respectively. In case

λDK equals zero, it recovers the Bingham–Papanastasiou model.

(3-24)

In case n equals one, it also recovers the Bingham–Papanastasiou model.

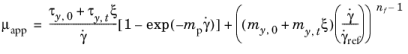

In the Ellis model, μapp is computed recursively using the following equation

(3-25)

where τ1/2 is the shear stress at which

μapp = μ0/2. The exponent

ae is the shear thinning index, which is a measure of the degree of nonlinearity.

where my,0 and

τy,0 denote the consistency and yield stress of the fully broken down material, respectively,

my,0 + my,t and

τy,0 + τy,t indicate the consistency and yield stress of the fully recovered material, respectively.

(3-26)

Here, the structure field ξ obeys the following equation:

where kf and

kb denote the rebuild and breakdown coefficients, respectively.

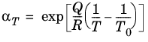

It is also possible to add the thermal effects to the non-Newtonian constitutive models. The following options: None,

Arrhenius,

Williams–Landel–Ferry (WLF),

Exponential, and

User defined are expressed in terms of a thermal function

αT. The thermal function

αT is coupled with the non-Newtonian constitutive models by multiplying by

μ0,

μp,

m,

μDK,

my,0, and

my,0 if they are

User defined.

(3-27)

where Q denotes the activation energy,

R is the universal gas constant,

T and

T0 are the temperature and reference temperature, respectively.

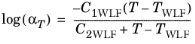

(3-28)

where C1WLF and

C2WLF are model constants, and

TWLF is the reference temperature.

(3-29)

where b denotes a temperature sensitivity, and

T0 is the reference temperature.