This section is available when temperature-dependent material properties are used. By default the temperature of the parent interface is used and the section is not editable. To edit the Temperature field, click

Make All Model Inputs Editable (

). The available options are

User defined (default),

Common model input, and all temperature variables from the physics interfaces included in the model. These physics interfaces have their own tags (the

Name). For example, if a

Heat Transfer in Fluids interface is included in the model, the

Temperature (ht) option is available.

The default Absolute pressure pA is taken from

Common model input. It corresponds to the

minput.pA variable, set to 1 atm by default. To edit it, click the

Go to Source button (

), and in the

Default Model Inputs node under

Global Definitions, set a value for the

Pressure in the

Expression for remaining selection section. When additional physics interfaces are added to the model, the absolute pressure variables defined by these physics interfaces can also be selected from the list. For example, if a

Laminar Flow interface is added you can select

Absolute pressure (spf) from the list. The last option is

User defined.

From the Concentration c (SI unit: mol/m

3 or kg/m

3) list, select an existing concentration variable from another physics interface, if any concentration variables exist, or select

User defined to enter a value or expression for the concentration. This section can be edited anytime a material property is concentration dependent; for example, when the

Fluid type is set to

Moist air with

Input quantity set to

Concentration.

The default Velocity field u is

User defined. For

User defined enter values or expressions for the components based on space dimensions. You can also select an existing velocity field in the component (for example,

Velocity field (spf) from a

Laminar Flow interface).

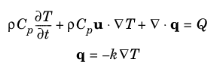

The thermal conductivity k describes the relationship between the heat flux vector

q and the temperature gradient

∇T in

q = −k∇T, which is Fourier’s law of heat conduction. Enter this quantity as power per length and temperature.

The default Thermal conductivity k is taken

From material. For

User defined select

Isotropic,

Diagonal,

Symmetric, or

Full based on the characteristics of the thermal conductivity, and enter another value or expression. For

Isotropic enter a scalar which will be used to define a diagonal tensor. For the other options, enter values or expressions into the editable fields of the tensor.

The heat capacity at constant pressure Cp describes the amount of heat energy required to produce a unit temperature change in a unit mass.

The ratio of specific heats γ is the ratio between the heat capacity at constant pressure,

Cp, and the heat capacity at constant volume,

Cv. When using the ideal gas law to describe a fluid, specifying

γ is sufficient to evaluate

Cp. For common diatomic gases such as air,

γ = 1.4 is the standard value. Most liquids have

γ = 1.1 while water has

γ = 1.0. γ is used in the streamline stabilization and in the variables for heat fluxes and total energy fluxes. It is also used if the ideal gas law is applied.

When the density is not taken from a Nonisothermal Flow or a

Nonisothermal Mixture Model coupling node, you should select a

Fluid type option for the specification of the material properties. The available

Fluid type options are

From material,

Ideal gas, and

Gas/Liquid (default). After selecting a

Fluid type from the list, further settings display underneath. See

Nonisothermal Mixture Model in the

CFD Module User’s Guide for details.

with Rs the specific gas constant,

pA the absolute pressure, and

T the temperature, the evaluation of the isobaric compressibility coefficient,

αp, and of the isothermal Joule-Thomson coefficient,

μJT, is simplified. This may improve efficiency, when computing pressure work in compressible nonisothermal flows for example, or when modeling inflow conditions.

The Density, the

Heat capacity at constant pressure, and the

Ratio of specific heats are automatically taken

From material and no further setting is required. For the specification of user defined material properties, the

Ideal Gas or

Gas/Liquid options should be used instead.

This option specifies the Density, the

Heat capacity at constant pressure, and the

Ratio of specific heats for a general gas or liquid.