where h = hw + hb and the tangential velocity,

vav, represents the mean velocity of the flow in the reference plane. Particular care must be taken with respect to the definition of

h. The above equation applies if

h is measured with respect to a fixed point on the reference surface as a function of time. The reference surface itself must be fixed in space and cannot deform as time progresses. Equations represented on the reference surface are described as Eulerian, that is they are defined in a frame that is fixed with respect to the motion of the fluid or of the body. Fluid flow problems are usually formulated in the Eulerian frame, and COMSOL Multiphysics adopts this convention in most of its fluid flow interfaces. It is useful to note that the Eulerian frame is usually called the spatial frame within the COMSOL Multiphysics interface. When a structure deforms in COMSOL Multiphysics, the spatial frame changes shape.

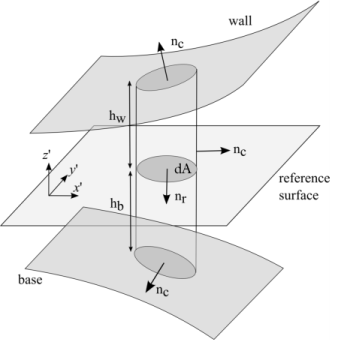

The situation encountered when both the wall and the base undergo a displacement is depicted in Figure 9-4. The Eulerian wall height changes from an initial value

hw1 to a final value

hw. Similarly the base height changes from an initial value

hb1 to

hb.