In this case, the device’s inlet is an external boundary, represented by the external circular boundary of the green domain on Figure 3-4. The device’s outlet is an interior face situated between the green and blue domains in

Figure 3-4. The lumped curve gives the flow rate as a function of the pressure difference between the external boundary and the interior face. This boundary condition implementation follows the

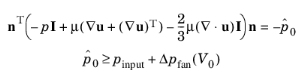

Pressure Boundary Condition for inlets with the Suppress backflow option:

Here, V0 is the flow rate across the boundary,

pinput is the pressure at the device’s inlet, and

Δpfan(V0) and

Δpgrille(V0) are the static pressure functions of flow rate for the fan and the grille.

Equation 3-41 and

Equation 3-42 correspond to the compressible formulation. For incompressible flows, the term

−(2/3)μ(∇ ⋅ u) vanishes. When a turbulence model with a transport equation for the turbulent kinetic energy is applied, the term

−(2/3)ρk appears on the left sides of

Equation 3-41 and

Equation 3-42. In such cases the turbulent kinetic energy,

k, the turbulent relative fluctuations,

ζ (for the v2-f turbulence model), and dissipation rate,

ε, or specific dissipation rate,

ω, must be specified on the downstream side. The turbulence conditions are specific to the design and operating conditions of the fan or grille. For the Fan condition, a reference velocity scale

Uref is available in order to set default values according to

Equation 3-40. For the Grille boundary condition the turbulence quantities on the downstream side are specified by defining a loss coefficient

K = 2Δpgrille/ρ(u ⋅ n)2, from which a refraction coefficient is derived using

Equation 3-55.

Equation 3-48 through

Equation 3-50 are then used to relate upstream and downstream turbulence quantities.

Here, the swirl ratio csf is a positive number less than 1, defining the ratio of the rotation transferred from the fan to the flow,

f is the number of revolutions per time for the fan, and

rbp is the rotation axis base point. The swirl velocity is defined on the maximum inscribed circular region on the fan inlet boundary. Hence, it is only applicable on simply connected flat boundaries. For more complicated inlet topologies, a swirl velocity can be defined by specifying the inlet velocity vector.

In this case (see Figure 3-14), the fan’s inlet is the interior face situated between the blue (cube) and green (circle) domain while its outlet is an external boundary, here the circular boundary of the green domain. The lumped curve gives the flow rate as a function of the pressure difference between the interior face and the external boundary. This boundary condition implementation follows the

Pressure Boundary Condition for outlets with the Suppress backflow option:

Here, V0 is the flow rate across the boundary,

pexit is the pressure at the device outlet, and

Δpfan(V0) and

Δpgrille(V0) are the static pressure function of flow rate for the fan and the grille.

Equation 3-43 and

Equation 3-44 correspond to the compressible formulation. For incompressible flows, the term

−(2/3)μ(∇ ⋅ u)n vanishes. When a turbulence model with a transport equation for the turbulence kinetic energy is applied, the term

−(2/3)ρkn appears on the left sides of

Equation 3-43 and

Equation 3-44. In 2D the thickness in the third direction,

Dz, is used to define the flow rate. Fans are modeled as rectangles in this case.