|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Boundary Mode Analysis.

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file mach_zehnder_modulator_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file mach_zehnder_modulator_geometry_parameters.txt.

|

|

1

|

|

2

|

In the Part Libraries window, select Wave Optics Module>Slab Waveguides>slab_waveguide_s_bend_directional_coupler in the tree.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Slab Waveguide S-Bend Directional Coupler 1 (pi1).

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

Click OK.

|

|

10

|

|

11

|

|

12

|

|

13

|

Click OK.

|

|

14

|

|

16

|

|

17

|

|

18

|

Click OK.

|

|

19

|

|

1

|

|

2

|

In the Part Libraries window, select Wave Optics Module>Slab Waveguides>slab_waveguide_straight in the tree.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Slab Waveguide Straight 1 (pi2).

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Slab Waveguide S-Bend Directional Coupler 1 (pi1) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 right-click Slab Waveguide Straight 1 (pi2) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

In the New Cumulative Selection dialog box, type End of Upper Mach-Zehnder Waveguide in the Name text field.

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

In the New Cumulative Selection dialog box, type End of Lower Mach-Zehnder Waveguide in the Name text field.

|

|

5

|

Click OK.

|

|

6

|

|

1

|

|

2

|

In the Settings window for Union Selection, type Edge Mesh in the Label text field. This selection will be used later when defining the selection for an edge mesh feature.

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) click Electromagnetic Waves, Beam Envelopes (ewbe).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click the Custom button.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Right-click Study 1>Step 2: Frequency Domain and choose Move Down three times, or simply drag and drop the frequency domain study step to the last position.

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

|

5

|

Click

|

|

6

|

|

7

|

|

8

|

|

9

|

Click Replace.

|

|

10

|

|

12

|

|

1

|

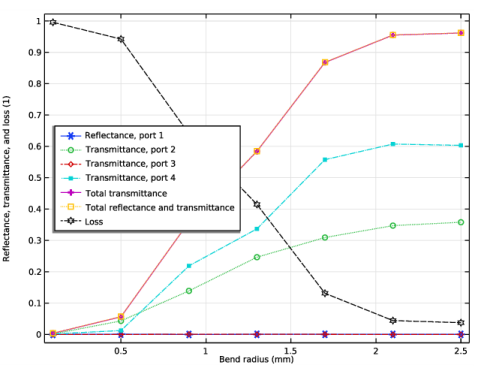

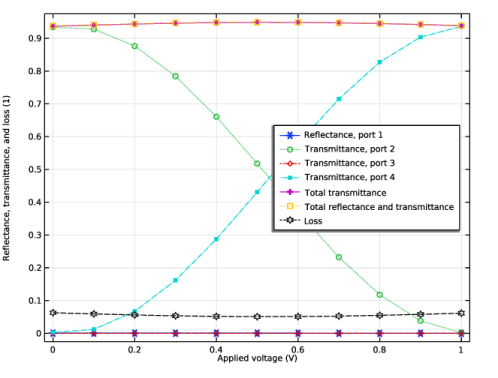

In the Model Builder window, under Results click Reflectance, Transmittance, and Absorptance (ewbe).

|

|

2

|

In the Settings window for 1D Plot Group, type Reflectance, Transmittance, and Loss (ewbe) in the Label text field.

|

|

3

|

Locate the Plot Settings section. In the y-axis label text field, type Reflectance, transmittance, and loss (1).

|

|

1

|

In the Model Builder window, expand the Reflectance, Transmittance, and Loss (ewbe) node, then click Global 1.

|

|

2

|

|

4

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

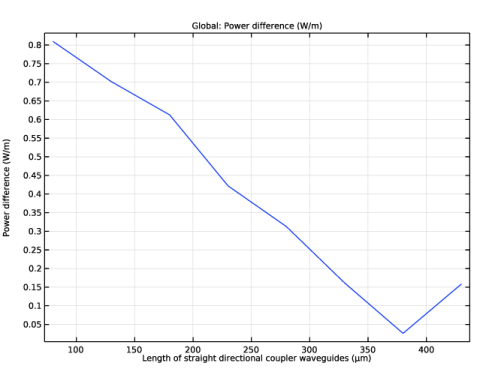

|

3

|

From the list in the Parameter name column, choose d_cpl (Length of straight directional coupler waveguides).

|

|

4

|

Click

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

9

|

|

1

|

In the Model Builder window, under Results>Reflectance, Transmittance, and Loss (ewbe) click Global 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the text field, type epsr.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the text field, type epsr.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

4

|

|

1

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

|

7

|

|

8

|

Click Replace.

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results>Reflectance, Transmittance, and Loss (ewbe) click Global 1.

|

|

2

|

|

3

|

|

4

|