|

|

•

|

Elastic data: instantaneous shear modulus G0 = 27.46 GPa and long-term shear modulus of G = μ0G0, bulk modulus K = 39.88 GPa.

|

|

•

|

|

•

|

Thermal properties: A WLF shift function is used with C1 = 17.44 and C2 = 51.6. These values are reasonable approximations for many polymers.

|

|

•

|

The reference temperature is 500 K.

|

|

•

|

|

•

|

Stationary analysis: The inner and outer circular edges both have a temperature distribution varying linearly with the y-coordinate from 500 K at the y = 0 symmetry section to 506 K at the x = 0 symmetry section.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

|

5

|

Click Add.

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click to expand the Layers section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object c1, select Domain 1 only.

|

|

5

|

|

1

|

|

2

|

|

3

|

From the list, choose Quasistatic.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Mechanics (solid) click Linear Elastic Material 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Click

|

|

6

|

Click

|

|

8

|

Click

|

|

10

|

|

11

|

|

12

|

Locate the Viscoelasticity Model section. From the Stiffness used in stationary studies list, choose Instantaneous.

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Stress (solid), Temperature (ht), and Isothermal Contours (ht).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Study, type Study: Transient (Constant Temperature) in the Label text field.

|

|

1

|

In the Model Builder window, under Study: Transient (Constant Temperature) click Step 1: Time Dependent.

|

|

2

|

|

3

|

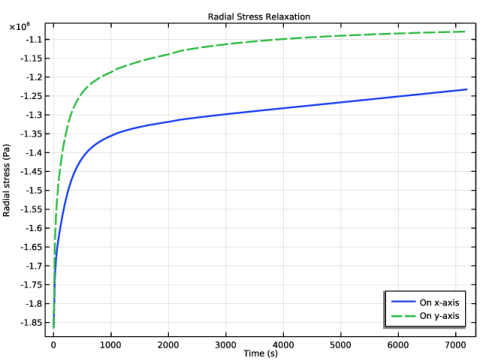

In the Output times text field, type range(0,20,200) range(250,50,1000) range(1100,100,2000) range(2200,200,7200).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Model Builder window, under Study: Transient (Constant Temperature)>Solver Configurations>Solution 2 (sol2) click Time-Dependent Solver 1.

|

|

9

|

|

10

|

|

11

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Data section. From the Dataset list, choose Study: Transient (Constant Temperature)/Solution 2 (sol2).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Data section. From the Dataset list, choose Study: Transient (Constant Temperature)/Solution 2 (sol2).

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>Stress tensor (spatial frame) - N/m²>solid.sxx - Stress tensor, xx-component.

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, right-click Stress Relaxation (Constant Temperature) and choose Point Graph.

|

|

2

|

|

3

|

|

4

|

Click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Stress>Stress tensor (spatial frame) - N/m²>solid.syy - Stress tensor, yy-component.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Stress (solid) 1, Temperature (ht) 1, Isothermal Contours (ht) 1, and Stress Relaxation (Constant Temperature).

|

|

2

|

Right-click and choose Group.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Output times text field, type range(0,20,200) range(250,50,1000) range(1100,100,2000) range(2200,200,7200).

|

|

3

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

4

|

|

5

|

Right-click and choose Disable.

|

|

6

|

|

7

|

In the Settings window for Study, type Study: Transient (Variable Temperature) in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

In the Model Builder window, under Study: Transient (Variable Temperature)>Solver Configurations>Solution 3 (sol3) click Time-Dependent Solver 1.

|

|

9

|

|

10

|

|

11

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Cut Point 2D 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Results>Datasets right-click Cut Point 2D 2 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, right-click Stress Relaxation (Constant Temperature) and choose Duplicate.

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Settings window for 1D Plot Group, type Stress Relaxation (Variable Temperature) in the Label text field.

|

|

1

|

In the Model Builder window, expand the Stress Relaxation (Variable Temperature) node, then click Point Graph 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Stress (solid) 2, Temperature (ht) 2, Isothermal Contours (ht) 2, and Stress Relaxation (Variable Temperature).

|

|

2

|

Right-click and choose Group.

|