|

|

•

|

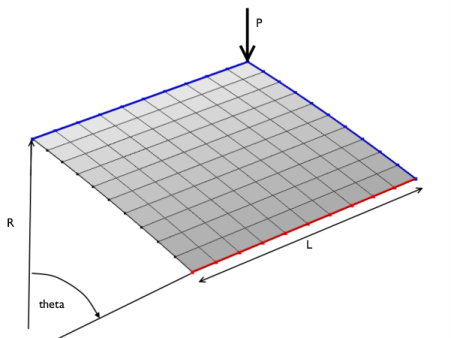

The radius of the cylinder is R = 2.54 m and all edges have a length of 2L = 0.508 m. The angular span of the panel is thus 0.2 radians. The panel thickness is th = 6.35 mm.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Click the Angles button.

|

|

4

|

|

5

|

Locate the Revolution Axis section. Find the Direction of revolution axis subsection. In the xw text field, type 1.

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Equation-Based Contributions.

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

Click

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

10

|

|

11

|

|

12

|

Click

|

|

13

|

|

14

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose Blank Material.

|

|

2

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node.

|

|

4

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Parametric 1 and choose Stop Condition.

|

|

5

|

|

6

|

Click

|

|

8

|

|

9

|

|

10

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1) click Stationary Solver 1.

|

|

11

|

|

12

|

|

13

|

Click

|

|

1

|

|

2

|

|

1

|

|

3

|

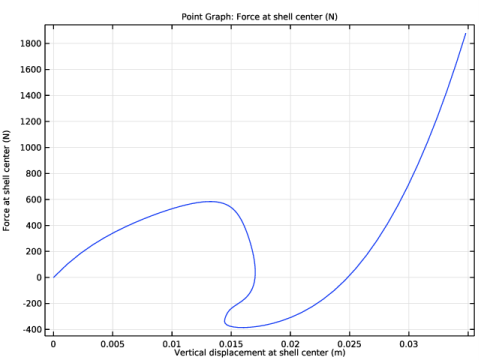

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Shell>P - Force at shell center - N.

|

|

4

|

|

5

|

|

6

|