|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file main_bearing_cap_geom.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

On the object imp1(1), select Boundary 4 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

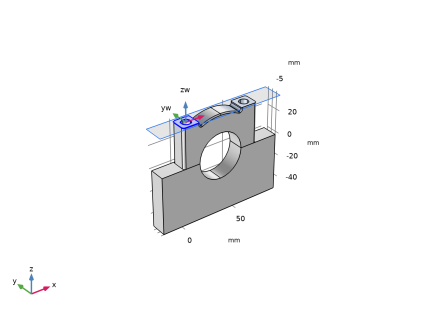

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Hex Bolt, With Drill 1 (pi1).

|

|

2

|

|

3

|

|

4

|

Locate the Position and Orientation of Output section. Find the Coordinate system in part subsection. From the Work plane in part list, choose Head inner plane (wp1).

|

|

5

|

Find the Coordinate system to match subsection. From the Work plane list, choose Work Plane 1 (wp1).

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

9

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

Locate the Position and Orientation of Output section. Find the Displacement subsection. In the xw text field, type 55.

|

|

1

|

|

2

|

Select the object imp1(2) only.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

In the Settings window for Adjacent, type Stress Area Reduced Domains Domains in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Materials right-click Structural steel (mat1) and choose Duplicate.

|

|

2

|

|

3

|

Locate the Geometric Entity Selection section. From the Selection list, choose Stress Area Reduced Domains Domains.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Identity Boundary Pair 1 (ap1).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

8

|

|

9

|

|

10

|

|

11

|

Click OK.

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1>Segregated 1 node, then click Solid Mechanics.

|

|

4

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

1

|

|

2

|

|

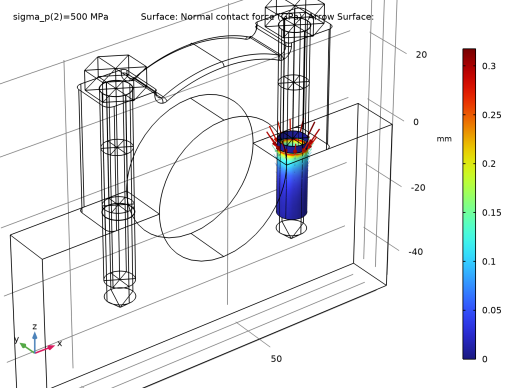

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Bolts>Bolt thread contact>solid.Fn_up - Normal contact force - N/m².

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

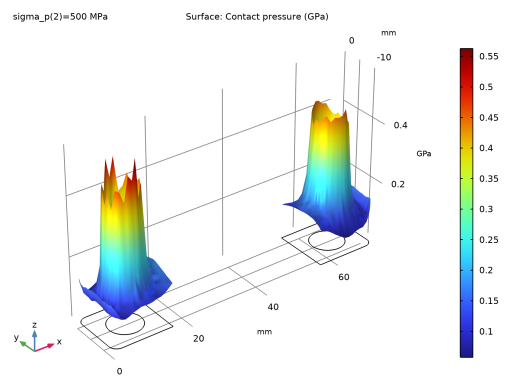

1

|

|

2

|

In the Settings window for 2D Plot Group, type Contact Pressure Between Caps in the Label text field.

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Contact>solid.Tn - Contact pressure - N/m².

|

|

3

|

|

1

|

|

2

|