|

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Solid Mechanics (solid) and Structural Mechanics>Beam (beam).

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file bolt_pretension_tutorial_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

Select the object cyl1 only.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Part Libraries window, select Structural Mechanics Module>Bolts>hex_bolt_no_thread in the tree.

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Hex Bolt, No Thread 1 (pi1).

|

|

2

|

|

4

|

Locate the Position and Orientation of Output section. Find the Displacement subsection. In the xw text field, type 20.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

11

|

|

12

|

|

13

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

4

|

Locate the Position and Orientation of Output section. Find the Displacement subsection. In the xw text field, type 20.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

In the Part Libraries window, select Structural Mechanics Module>Bolts>simple_bolt_drill in the tree.

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Simple Bolt, With Drill 1 (pi3).

|

|

2

|

|

4

|

Locate the Position and Orientation of Output section. Find the Displacement subsection. In the xw text field, type 20.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

Select the object pi3(2) only.

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for Difference, type Difference: Bolt Holes and Cavity, Upper in the Label text field.

|

|

3

|

Select the object blk2 only.

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

In the Settings window for Difference, type Difference: Bolt Holes and Cavity, Lower in the Label text field.

|

|

3

|

Locate the Difference section. Find the Objects to add subsection. Click to select the

|

|

4

|

Select the object blk1 only.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

On the object dif1, select Point 2 only.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

Select the object c1 only.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. Click New.

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

Select the object pol1 only.

|

|

4

|

|

5

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Bolts and Nuts.

|

|

6

|

|

1

|

|

2

|

|

3

|

Locate the Coordinates section. In the table, enter the following settings:

|

|

4

|

Locate the Selections of Resulting Entities section. Find the Cumulative selection subsection. From the Contribute to list, choose Beams.

|

|

5

|

|

6

|

|

1

|

In the Model Builder window, expand the Component 1 (comp1)>Definitions>View 1 node, then click Clip Plane 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Specify the V vector as

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

From the list, choose Nitsche.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

6

|

|

8

|

|

1

|

|

2

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Connection Settings section. From the Connection type list, choose Solid edges to beam points.

|

|

4

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

5

|

|

7

|

Locate the Connection Settings section. From the Connected region list, choose Connection criterion.

|

|

8

|

In the text field, type Z>thicLow-boltDia/2.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Locate the Definition section. In the Expression text field, type time==1 || abs(time-active)<0.001 || abs(time-full)<0.001.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

In the text field, type Bolt_4.

|

|

4

|

Locate the Boundary Selection section. From the Selection list, choose Pretension cut (Simple Bolt, With Drill 1).

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the text field, type Bolt_2.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

Right-click Component 1 (comp1)>Beam (beam)>Bolt Pretension 1>Bolt Selection 1 and choose Duplicate.

|

|

2

|

|

3

|

In the text field, type Bolt_3.

|

|

4

|

|

6

|

|

7

|

|

1

|

|

3

|

|

4

|

In the text field, type Bolt_5.

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Definitions click Identity Boundary Pair 1a (ap1).

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

Click the Custom button.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

1

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 node, then click Displacement field (material and geometry frames) (comp1.beam.uLin).

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 1 click Rotation field (material and geometry frames) (comp1.beam.thLin).

|

|

6

|

|

7

|

|

8

|

|

9

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 node, then click Fully Coupled 1.

|

|

10

|

|

11

|

|

12

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 click Parametric 1.

|

|

13

|

|

14

|

|

15

|

|

16

|

|

17

|

|

18

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 click Advanced.

|

|

19

|

|

20

|

|

21

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Stationary Solver 1 click Fully Coupled 1.

|

|

22

|

|

23

|

Select the Plot check box.

|

|

24

|

|

1

|

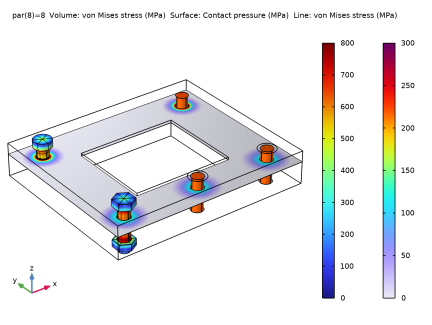

In the Settings window for 3D Plot Group, type Bolt Stress and Contact Pressure in the Label text field.

|

|

2

|

Click to collapse the Data section.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Contact>solid.Tn - Contact pressure - N/m².

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

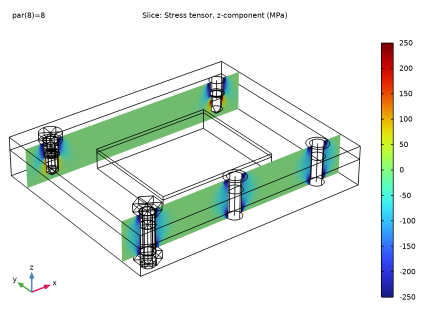

In the Settings window for 3D Plot Group, type Transverse Stress in the Bolt Planes in the Label text field.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

In the tree, select Component 1 (comp1)>Solid Mechanics (solid), Controls spatial frame>Boundary Load 1.

|

|

5

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

7

|

Click to expand the Values of Dependent Variables section. Find the Initial values of variables solved for subsection. From the Settings list, choose User controlled.

|

|

8

|

|

9

|

|

10

|

Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 2>Solver Configurations>Solution 2 (sol2)>Dependent Variables 1 node, then click Rotation field (material and geometry frames) (comp1.beam.thLin).

|

|

4

|

|

5

|

|

6

|

|

7

|

In the Model Builder window, under Study 2>Solver Configurations>Solution 2 (sol2)>Dependent Variables 1 click Displacement field (material and geometry frames) (comp1.beam.uLin).

|

|

8

|

|

9

|

|

10

|

|

11

|

In the Model Builder window, expand the Study 2>Solver Configurations>Solution 2 (sol2)>Stationary Solver 1 node, then click Advanced.

|

|

12

|

|

13

|

|

14

|

|

1

|

|

2

|

In the Settings window for 3D Plot Group, type Bolt Stress and Contact Pressure, Service Load in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Replace Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Bolts>Bolt_1>solid.pblt1.sblt1.M_pre - Tightening torque - N·m.

|

|

1

|

|

2

|

|

3

|

|

4

|