|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

On the object pol1, select Point 3 only.

|

|

3

|

|

4

|

|

1

|

|

2

|

On the object fil1, select Point 3 only.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

2

|

In the Settings window for Boundary Load, type Boundary Load: Axial Extension in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 2 (comp2)>Geometry 2 right-click Work Plane 1 (wp1) and choose Revolve.

|

|

2

|

|

1

|

|

2

|

In the Settings window for Cylindrical System, type Cylindrical System (Material Frame) in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

In the Settings window for Boundary Load, type Boundary Load: Axial Extension in the Label text field.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

4

|

Locate the Coordinate System Selection section. From the Coordinate system list, choose Cylindrical System (Material Frame) (sys3).

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

6

|

Click

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click

|

|

7

|

|

1

|

|

2

|

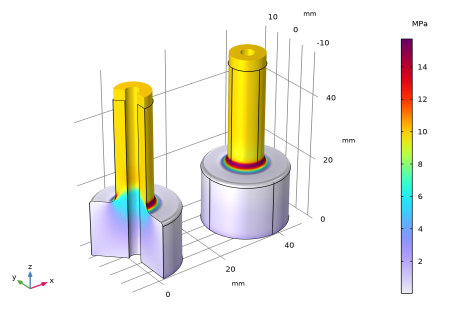

In the Settings window for 3D Plot Group, type Stress: Axial Extension & Torsion (2D axi & 3D) in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Stress: Axial Extension & Torsion (2D axi & 3D) node, then click Surface 1.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, right-click Stress: Axial Extension & Torsion (2D axi & 3D) and choose Surface.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Results>Stress, 3D (solid) 1 node, then click Stress, 3D (solid) 1.

|

|

2

|

In the Settings window for 3D Plot Group, type Stress: Bending (2D axi & 3D) in the Label text field.

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for Evaluation Group, type Stress Concentration Factors in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Expressions section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Locate the Expressions section. In the table, enter the following settings:

|

|

7

|