|

|

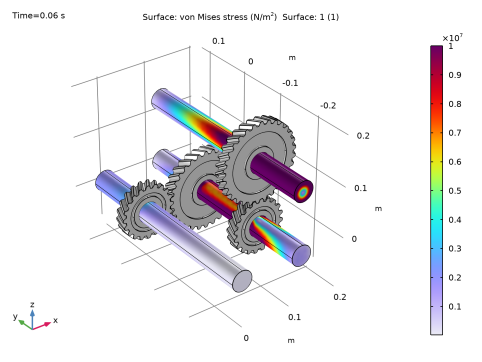

2·106 N/m

|

|

•

|

In the time dependent analysis, a resisting load torque of 102 Nm is applied at the opposite end of the driven shaft.

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file geared_rotors_parameters.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file geared_rotors.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the text field, type omega.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

|

3

|

|

4

|

In the text field, type -omega/gr.

|

|

1

|

|

3

|

|

4

|

In the text field, type omega/gr^2.

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

In the Model Builder window, expand the Helical Gear 1 node, then click Center of Rotation: Point 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld) right-click Helical Gear 1 and choose Duplicate.

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, expand the Helical Gear 2 node, then click Center of Rotation: Point 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld) right-click Helical Gear 1 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Helical Gear 3 node, then click Center of Rotation: Point 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Solid Rotor (rotsld) right-click Helical Gear 2 and choose Duplicate.

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, expand the Helical Gear 4 node, then click Center of Rotation: Point 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

3

|

|

4

|

Specify the Orientation vector defining local y direction vector as

|

|

5

|

Locate the Bearing Properties section. From the Bearing model list, choose Total spring and damping constant.

|

|

6

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

5

|

|

1

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the tree, select Study 1: Eigenfrequency/Parametric Solutions 1 (sol2)>Solid Rotor>Campbell Plot, Rotating Frame (rotsld).

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

In the Model Builder window, under Results>Campbell Plot, Rotating Frame (rotsld) click Forward Whirl Mode.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Clear the Prefix text field.

|

|

9

|

|

10

|

|

11

|

Click Define custom colors.

|

|

13

|

Click Add to custom colors.

|

|

14

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

|

6

|

Click

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

9

|

|

10

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Frequency response: x-displacement in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

In the Model Builder window, expand the Frequency response: x-displacement 1 node, then click Global 1.

|

|

2

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Frequency response: z-rotation in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

In the Model Builder window, expand the Study 3: Time Dependent>Solver Configurations>Solution 110 (sol110)>Time-Dependent Solver 1 node, then click Fully Coupled 1.

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Deformation, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Solid Rotor>Displacement>rotsld.us_fix,...,rotsld.ws_fix - Displacement field, fixed frame.

|

|

3

|

Locate the Scale section.

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Point Data section. In the X text field, type rotsld.hlg1.xcx, rotsld.hlg2.xcx, rotsld.hlg3.xcx, rotsld.hlg4.xcx.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click to expand the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Model Builder window, expand the Gear orbits, rotating frame 1 node, then click Point Graph 1.

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Coloring and Style section. Find the Line style subsection. From the Line list, choose Cycle.

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

1

|

|

2

|

|

3

|

|

4

|