|

|

•

|

f (SI unit: W/(m2 steradian)) is the radiant intensity

|

|

•

|

Ω denotes surface integration over the collector surface

|

|

•

|

|

•

|

|

•

|

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Part Libraries window, select Ray Optics Module>3D>Mirrors>paraboloidal_reflector_shell_3d in the tree.

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Geometry 1 click Paraboloidal Reflector Shell 3D 1 (pi1).

|

|

2

|

|

4

|

Locate the Position and Orientation of Output section. Find the Displacement subsection. In the zw text field, type -f.

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

Click

|

|

5

|

Browse to the model’s Application Libraries folder and double-click the file solar_dish_receiver_reference.txt.

|

|

6

|

Click

|

|

7

|

|

8

|

In the Function table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Browse to the model’s Application Libraries folder and double-click the file solar_dish_receiver_variables.txt.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Intensity Computation section. From the Intensity computation list, choose Compute power.

|

|

5

|

Locate the Ray Release and Propagation section. In the Maximum number of secondary rays text field, type 0.

|

|

1

|

|

2

|

In the Settings window for Illuminated Surface, type Ideal Illuminated Surface in the Label text field.

|

|

3

|

Locate the Boundary Selection section. From the Selection list, choose All (Paraboloidal Reflector Shell 3D 1).

|

|

4

|

|

5

|

|

6

|

|

7

|

Locate the Angular Perturbations section. From the Corrections for finite source diameter list, choose Sample from conical distribution.

|

|

8

|

|

9

|

|

1

|

|

2

|

In the Settings window for Illuminated Surface, type Real Illuminated Surface in the Label text field.

|

|

3

|

Locate the Boundary Selection section. From the Selection list, choose All (Paraboloidal Reflector Shell 3D 1).

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Locate the Angular Perturbations section. From the Corrections for finite source diameter list, choose Sample from conical distribution.

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

14

|

Locate the Incident Ray Polarization section. From the Initial polarization type list, choose Unpolarized.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

5

|

|

6

|

|

7

|

|

8

|

|

9

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

6

|

|

7

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

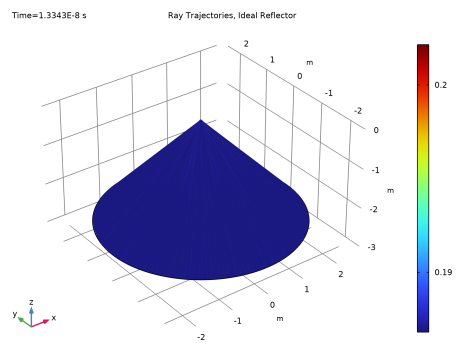

In the Settings window for 3D Plot Group, type Ray Trajectories, Ideal Reflector in the Label text field.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Ray Trajectories, Ideal Reflector>Ray Trajectories 1 node, then click Color Expression 1.

|

|

2

|

In the Settings window for Color Expression, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Geometrical Optics>Intensity and polarization>gop.Q - Ray power - W.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Deposited Power, Ideal Reflector in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

In the Settings window for Surface, click Replace Expression in the upper-right corner of the Expression section. From the menu, choose Component 1 (comp1)>Geometrical Optics>Accumulated variables>Boundary heat source comp1.gop.wall1.bsrc1.Qp>gop.wall1.bsrc1.Qp - Boundary heat source - W/m².

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Concentration Ratios, Ideal Reflector in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

|

10

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Legends section. In the table, enter the following settings:

|

|

6

|

|

1

|

|

2

|

|

3

|

Find the Studies subsection. In the Select Study tree, select Preset Studies for Selected Physics Interfaces>Ray Tracing.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Physics and Variables Selection section. Select the Modify model configuration for study step check box.

|

|

5

|

|

6

|

Right-click and choose Disable.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

In the Settings window for 3D Plot Group, type Ray Trajectories, Real Reflector in the Label text field.

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Results>Ray Trajectories, Real Reflector>Ray Trajectories 1 node, then click Color Expression 1.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Deposited Power, Real Reflector in the Label text field.

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, right-click Concentration Ratios, Ideal Reflector and choose Duplicate.

|

|

2

|

In the Settings window for 1D Plot Group, type Concentration Ratios, Real Reflector in the Label text field.

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, expand the Concentration Ratios, Real Reflector node, then click Line Graph 1.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

In the Settings window for 2D Plot Group, type Deposited Power, Real and Ideal Reflectors in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, right-click Deposited Power, Real and Ideal Reflectors and choose Annotation.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|