|

.

.

|

1

|

|

2

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Solid Mechanics (solid) and choose Volume Forces>Rotating Frame.

|

|

2

|

|

3

|

|

1

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Physics Utilities>Mass Properties.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Locate the Expressions section. In the table, enter the following settings:

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

1

|

|

3

|

|

4

|

|

5

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Definitions and choose Variables.

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the table, clear the Solve for check boxes for Deformed geometry (Component 1) and Shape Optimization (Component 1).

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Definitions>Mass Properties 1>Moment of inertia, principal values>comp1.mass1.Ip1 - First moment of inertia principal value - kg·m².

|

|

5

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Definitions>Free Shape Domain 1>comp1.fsd1.relVolume - Material volume divided by geometry volume.

|

|

6

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Definitions>Variables>comp1.stress_Pnorm - Scaled P-norm of von Mises stress.

|

|

7

|

Locate the Objective Function section. From the Objective scaling list, choose Initial solution based.

|

|

8

|

|

9

|

Locate the Constraints section. In the table, enter the following settings:

|

|

10

|

|

11

|

|

12

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

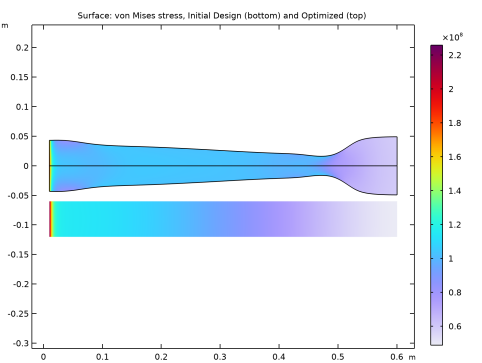

In the Title text area, type Surface: von Mises stress, Initial Design (bottom) and Optimized (top).

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Locate the Scale section.

|

|

6

|

|

7

|