|

|

1

|

|

2

|

|

3

|

Click

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

In the Settings window for Global Evaluation, click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Global>solid.Ws_tot - Total elastic strain energy - J.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

8

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Locate the Variables section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Control Variable Settings section. In the dmax text field, type 3[mm], which corresponds to twice the maximum displacement.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

Click Add Expression in the upper-right corner of the Objective Function section. From the menu, choose Component 1 (comp1)>Definitions>Variables>comp1.obj - Objective function.

|

|

6

|

|

7

|

|

8

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Definitions>Free Shape Domain 1>comp1.fsd1.relVolume - Material volume divided by geometry volume.

|

|

9

|

Click Add Expression in the upper-right corner of the Constraints section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Global>comp1.solid.Ws_tot - Total elastic strain energy - J.

|

|

10

|

Locate the Constraints section. In the table, enter the following settings:

|

|

11

|

|

1

|

In the Model Builder window, under Results, Ctrl-click to select Stress (solid) 1 and Applied Loads (solid) 1.

|

|

2

|

Right-click and choose Delete.

|

|

1

|

In the Model Builder window, expand the Optimized Design>Solver Configurations>Solution 3 (sol3) node, then click Optimization Solver 1.

|

|

2

|

|

3

|

|

4

|

In the Model Builder window, expand the Optimized Design>Solver Configurations>Solution 3 (sol3)>Optimization Solver 1>Stationary 1>Segregated 1 node, then click Solid Mechanics.

|

|

5

|

|

6

|

From the Linear solver list, choose Suggested Iterative Solver (solid)to reduce the computational time further.

|

|

1

|

|

2

|

|

3

|

Select the Plot check box.

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

In the Model Builder window, under Initial Fatigue, Ctrl-click to select Parametric Sweep and Step 1: Fatigue.

|

|

2

|

Right-click and choose Copy.

|

|

1

|

|

2

|

|

1

|

|

2

|

Find the Values of variables not solved for subsection. From the Study list, choose Optimized Design, Stationary.

|

|

3

|

|

1

|

|

2

|

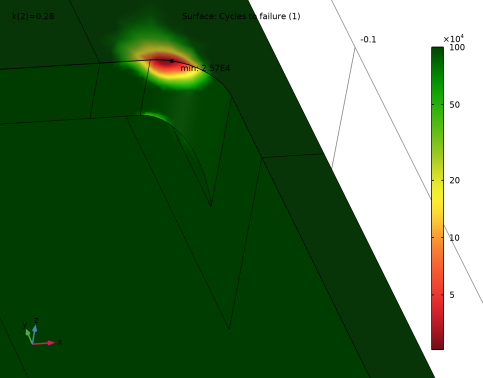

In the Settings window for 3D Plot Group, type Cycles to Failure, Optimized in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

Click Add Expression in the upper-right corner of the Expressions section. From the menu, choose Component 1 (comp1)>Fatigue>ftg.ctf - Cycles to failure.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

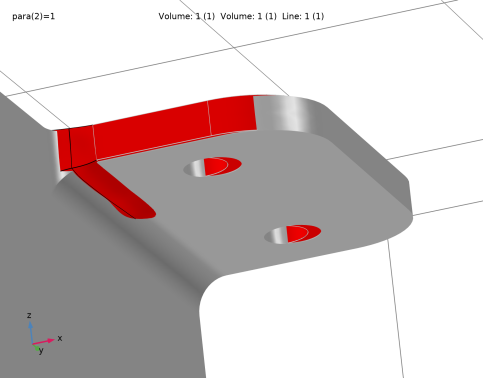

In the Settings window for 3D Plot Group, type Shape Optimization, Volumetric in the Label text field.

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|