|

|

1.49·107 1/s

|

||

|

1

|

|

2

|

In the Select Physics tree, select Structural Mechanics>Thermal-Structure Interaction>Thermal Stress, Solid.

|

|

3

|

Click Add.

|

|

4

|

Click

|

|

5

|

|

6

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

Locate the Definition section. In the Expression text field, type (flc2hs(x-0.1,0.1)*50)-flc2hs(x-(4.1),0.1)*40.

|

|

4

|

Locate the Units section. In the table, enter the following settings:

|

|

5

|

|

1

|

|

2

|

|

3

|

Click

|

|

4

|

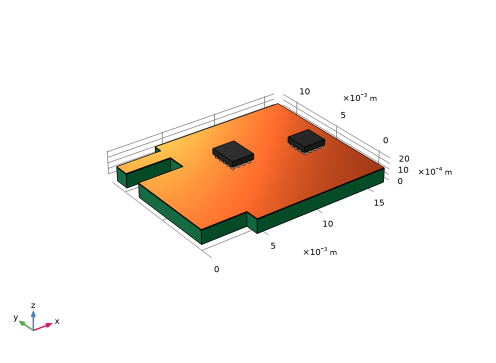

Browse to the model’s Application Libraries folder and double-click the file viscoplastic_solder_joints.mphbin.

|

|

5

|

Click

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

Click OK.

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Multiphysics click Thermal Expansion 1 (te1).

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

Find the Expression for remaining selection subsection. In the Volume reference temperature text field, type T0.

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the Show More Options dialog box, in the tree, select the check box for the node Physics>Advanced Physics Options.

|

|

6

|

Click OK.

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

3

|

|

4

|

|

1

|

In the Model Builder window, under Component 1 (comp1)>Heat Transfer in Solids (ht) click Initial Values 1.

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

In the tree, select Built-in>Copper.

|

|

6

|

|

7

|

In the tree, select Built-in>Silicon.

|

|

8

|

|

9

|

|

10

|

|

11

|

|

1

|

In the Model Builder window, under Component 1 (comp1) right-click Materials and choose More Materials>Material Link.

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

In the Material properties tree, select Solid Mechanics>Viscoplastic Material>Anand Viscoplasticity.

|

|

4

|

|

5

|

|

Ω·m

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

1

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Output times text field, type 0 0.005 range(0.025,0.025,0.5) range(0.75,0.25,3.75) 3.975 4+{range(0,0.025,0.5) range(0.75,0.25,2)}.

|

|

5

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Solid Mechanics (solid).

|

|

1

|

|

2

|

|

3

|

|

4

|

In the Output times text field, type 0 0.005 range(0.025,0.025,0.5) range(0.75,0.25,3.75) 3.975 4+{range(0,0.025,0.5) range(0.75,0.25,2)}.

|

|

5

|

Locate the Physics and Variables Selection section. In the table, clear the Solve for check box for Heat Transfer in Solids (ht).

|

|

6

|

Click to expand the Values of Dependent Variables section. Find the Values of variables not solved for subsection. From the Settings list, choose User controlled.

|

|

7

|

|

8

|

|

9

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Dependent Variables 2 node, then click Viscoplastic dissipation density (comp1.solid.Wvp).

|

|

7

|

|

8

|

|

9

|

|

10

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1) click Time-Dependent Solver 2.

|

|

11

|

|

12

|

|

13

|

|

14

|

Find the Algebraic variable settings subsection. From the Error estimation list, choose Exclude algebraic.

|

|

15

|

Right-click Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 2 and choose Segregated.

|

|

16

|

|

17

|

|

18

|

In the Model Builder window, expand the Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 2>Segregated 1 node, then click Segregated Step.

|

|

19

|

|

20

|

Locate the General section. In the Variables list, select Viscoplastic dissipation density (comp1.solid.Wvp).

|

|

21

|

|

22

|

Click to expand the Method and Termination section. From the Termination technique list, choose Tolerance.

|

|

23

|

|

24

|

In the Model Builder window, under Study 1>Solver Configurations>Solution 1 (sol1)>Time-Dependent Solver 2 right-click Segregated 1 and choose Segregated Step.

|

|

25

|

|

26

|

|

27

|

|

28

|

|

29

|

In the Add dialog box, select Viscoplastic dissipation density (comp1.solid.Wvp) in the Variables list.

|

|

30

|

Click OK.

|

|

31

|

|

1

|

|

2

|

|

3

|

|

1

|

|

2

|

|

3

|

|

4

|

|

1

|

|

2

|

In the Settings window for 1D Plot Group, type Deformation Resistance History in the Label text field.

|

|

3

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

Locate the Legends section. In the table, enter the following settings:

|

|

1

|

|

2

|

|

3

|

|

4

|

|

5

|

|

6

|

|

7

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Solid Mechanics>Energy and power>solid.WvpGp - Viscoplastic dissipation density - J/m³.

|

|

3

|

|

1

|

|

2

|

|

1

|

|

2

|

|

1

|

|

2

|

In the Settings window for Point Graph, click Replace Expression in the upper-right corner of the y-Axis Data section. From the menu, choose Component 1 (comp1)>Heat Transfer in Solids>Temperature>T - Temperature - K.

|

|

3

|

|

4

|